Frequently Asked Questions

About the Global Steel Climate Council®

Steel producers – irrespective of their steel production technology route – that are committed to a decarbonized and Net Zero future and willing to hold themselves accountable to these goals may be members of the GSCC®. Furthermore, upstream suppliers – including raw materials, technology solutions providers, equipment suppliers and others – as well as downstream customers are welcome as Associate Members of the GSCC®. We also count a number of trade associations that represent companies along the steel value chain as Association Member/Supporters.

About the Steel Climate Standard

Steel is an essential engineering material for the global economy. It is a critical material used to manufacture vehicles and machinery, build infrastructure, buildings and factories, produce energy and much more. Steel is also essential for the transition to clean technology products such as electric vehicles, wind turbines and solar arrays. A global steel standard will reduce carbon emissions and accelerate the transition to climate-sustaining steel products by providing a technically sound, consistent approach to measuring steel’s carbon intensity and disclosing this information to steel industry stakeholders, thereby incentivizing steelmakers around the world to pursue lower-emitting steel production processes and technologies.

A standard must lead to the global steel industry achieving meaningful reductions in carbon emissions. The Steel Climate Standard is a science-based emissions standard based on actual emissions that applies to all producers equally on a global basis. The Standard incentivizes technological innovation and immediate action, generating the largest decrease in carbon emissions towards the common sector goal for the steel industry to achieve the Paris Climate Agreement’s 1.5°C objective by 2050. Without this motivation, higher emission processes are allowed to remain unabated, delaying reduction of the global industry’s carbon footprint.

The Steel Climate Standard creates a single, science-based, ambitious, verifiable, technology-neutral framework that is achieving real carbon emissions reduction. In contrast, others advocate standards that feature a “ferrous scrap sliding scale” relative to use of scrap steel for setting carbon reduction trajectories. This approach sets a dual standard for emissions from steel producers with one benchmark for steel made from traditional production processes, and another for steel made from circular processes. As a result, a steel product manufactured by a traditional integrated mill and the same product produced by a circular mini mill would both be labeled as “green” under a “sliding scrap scale” standard, even though the first has a much higher carbon intensity than the second. This approach does not motivate swift and ambitious climate action.

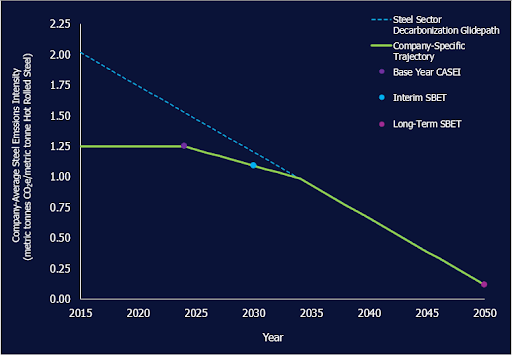

By way of example, if Company A starts with a CASEI of 1.25 metric tonnes CO2e/metric ton hot rolled steel in base year 2024 (i.e., below the glidepath), it would have an interim SBET of 1.09 metric tonnes CO2e/metric ton hot rolled steel by 2030. This represents an almost 13 percent reduction in the company’s CASEI over a six-year period. This is illustrated in Figure 1 below.

Figure 1. Company Glidepath Example: Base Year Below the Glidepath

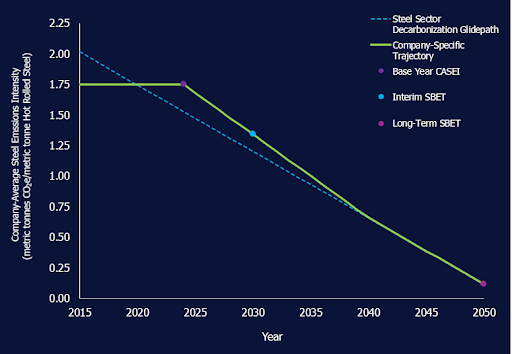

By contrast, if Company B starts with a CASEI of 1.75 metric tonnes CO2e/metric ton hot rolled steel in base year 2024 (i.e., above the glidepath) it would have an interim SBET of 1.34 metric tonnes CO2e/metric ton hot rolled steel by 2030. This represents a 23 percent reduction in the company’s CASEI over a six-year period. Also, Company B would have almost 10 years to reach the 1.09 metric tonnes CO2e/metric ton hot rolled steel target that Company A is expected to meet in 6 years. This is illustrated in Figure 2 below.

Figure 2. Company Glidepath Example: Base Year Above the Glidepath

The Steel Climate Standard acknowledges that each steel producer’s journey toward Net Zero is unique and that there are many ways for a company to lower steel production emissions. For that reason, the Standard incorporates the latest scientific projections and existing international calculation methodologies as a basis for the Standard’s Decarbonization Glidepath. Company-specific trajectories are determined in Section 6.7 of the Standard, noting that companies with a starting point below the Glidepath are recognized for decarbonization achievements already made but where more work needs to be done; and companies with a starting point above the Glidepath must show immediate progress but are provided a longer time horizon to converge with the GSCC® Glidepath. Unlike other programs, this approach incentivizes both near-term and long-term emissions reduction action.

Through comprehensive study of existing standards and intense consultation with steel producers and stakeholders, the GSCC® created the Steel Climate Standard that incorporates existing ISO and GHG Protocol frameworks and fills some carbon accounting gaps to yield a conservative yet true assessment and decarbonization ambition that applies to all steel producers equally, globally and with technology neutrality.

We published a draft of the Steel Climate Standard in April 2023 and invited comments from interested stakeholders. We reviewed all comments and made revisions ahead of publishing the final Steel Climate Standard in August 2023. A supplemental technical guidance was subsequently published in March 2024 to establish the GSCC®’s system for certifying conformity with the Steel Climate Standard, and public comments were also received, reviewed and where applicable, incorporated. The final supplemental technical guidance was published in April 2024. Both documents have undergone minor, editorial revisions since they were first published, and the current versions are available on the GSCC® website.

The GSCC® and the Steel Climate Standard are founded on a clear vision for the future of steel in a decarbonizing economy regardless of the technology and production methods utilized. The Standard holds all producers to the same accountability for cutting carbon emissions, which recognizes that many steel manufacturers have already made significant investments in lower carbon technology. The Standard provides market drivers for near-term reductions from the highest emitting sources and incentivizes long-term investment in emerging technology needed to meet the 2050 net zero goal.

The use of scrap as the predominant raw material is the least expensive, commercially available means of reducing the carbon emissions from steel production. The more recycled scrap that is used in steelmaking, the lower the industry’s carbon output. Globally, there is a dynamic and growing market for scrap, which has evolved, and will continue to evolve, to meet market demand, and steel companies have become efficient in their efforts to collect, process and utilize scrap.

Proponents of “sliding scrap scale” steel standards claim that forecasted steel demand requires continued use of traditional processes because there is insufficient scrap supply to meet that demand using circular processes. If that is so, then the sliding scale gives no indication as to how other business strategies and technological investments are incentivized. Nevertheless, these scrap scarcity claims assume an average steel product lifetime of 40 years. However, a recent report from the Steel Manufacturers Association (SMA) summarizing steel product lifetimes in the nine largest steel-producing countries globally indicates that, in all of the countries surveyed, steel product lifetimes are below 40 years, with some as low as 25 years. Hence, even without focused initiatives around steel circularity, current steel product lifetime data indicates that more scrap will be available sooner to meet the rising demand.

Rather than try to predict the availability of scrap or the evolution of emerging technological advancements, the Steel Climate Standard is the same for all producers, regardless of steel manufacturing technology, business strategy and ambition to decarbonize. As a result, its adoption by the market incentivizes steel producers to prioritize the pursuit of additional scrap-based production, which will drive steel circularity, while also incentivizing the investment in other emerging technologies, rather than prolonging the use of much higher-emitting production.

The Steel Climate Standard defines a clear boundary for relevant processes in the steelmaking value chain, regardless of whether they are a company’s Scope 1, Scope 2 and Scope 3 sources and includes the seven GHG pollutants covered under the Kyoto Protocol. The Standard also recognizes several ways to reduce steel’s carbon footprint within this boundary, from increased scrap use and increasing operational efficiency, to the use of contractual instruments for renewable energy, Renewable Thermal Certificates (RTCs) for renewable natural gas and the use of bio-based materials that are sustainably sourced and process off-gases recovered for reheating and to generate electricity.

No, carbon offsets and insets are excluded. Further, the life cycle emissions associated with steelmaking may not be allocated between products and co-products. These measures seek to promote decarbonization of processes that are within the Standard’s boundary and sustainable practices relevant to steelmaking, thereby leading to effective emissions reductions. These restrictions also enhance product comparability for steel customers by disallowing allocation calculations that are not well defined or uniformly applied.

While the GSCC® recognizes that certain impact categories such as water usage and biodiversity are intrinsically linked to climate change, expansion of the standard to address these issues has not been contemplated at this time. However, the Standard will be reviewed at least every five years to ensure that it remains current and relevant. As such, inclusion of other environmental impact categories, particularly as they may be impacted by certain decarbonization strategies selected, may be addressed during a later revision to the Standard.

GSCC® Certification

Certification is initiated by the member company contracting with a GSCC®-approved certification body. The list of approved certification bodies and their contact information are provided on GSCC®’s website here. The certification procedures are detailed in the Supplemental Technical Guidance document provided on GSCC®’s website here.

No, the Steel Climate Standard requires companies who wish to adopt the product standards to establish and publicly disclose SBETs within two years of joining the GSCC® as a condition of their participation in the program. While certification of steel products is optional, establishment of SBETs is required. This requirement demonstrates the GSCC®’s commitment to incentivizing real reductions within the steel industry needed to achieve the Paris Climate Agreement’s 1.5°C objective by 2050.

However, this is the GSCC®’s value proposition: combining product certification with corporate-wide emissions reduction strategy. Although not required, steel producers may seek product certification to meet customer disclosure requirements seeking the emissions intensity information of the steel products that they purchase. The Steel Climate Standard requires that the product’s emissions intensity is self-audited annually and re-audited by a third party certification body every three years. This signals to the customer that the emissions intensity of the steel they are purchasing is in constant decline.

The SBET is established based on the company-average steel emissions intensity (CASEI) which is a corporate-wide assessment of emissions from sources within the company’s entire portfolio’s value chain that are identified within the GSCC® boundary. This value is calculated using a corporate GHG emissions accounting approach as outlined in Section 6 of The Steel Climate Standard.

The steel product intensity is a facility-specific assessment of the cradle-to-gate life cycle emissions associated with a given product. This value is calculated using a product life cycle accounting approach as outlined in Section 4 of The Steel Climate Standard.

Companies that meet the requirements for certification bodies outlined in Section 4 of the GSCC®’s Supplemental Technical Guidance may apply to become a GSCC®-approved certification body by completing the application form provided on GSCC®’s website here. These applications are reviewed by the GSCC®’s Technical Committee to ensure that they meet the established criteria. Once approved, the certification body receives training on the Steel Climate Standard and certification processes.

Global Engagement

Our intent in developing the Steel Climate Standard was to guide the steel industry on a path toward decarbonization. The Standard was presented to negotiators in both markets, as well as other countries and multilateral organizations, to help guide industrial and climate policymaking.

The CSRD entered into force on January 5, 2023, and requires large companies operating in the EU, or international companies that generate a certain level of revenue in the EU, to disclose sustainability information according to the ESRS. These standards require the reporting company to assess the double materiality of a wide range of sustainability topics (both environmental and social) and then disclose the required information for topics deemed material. The Steel Climate Standard addresses climate change only, presuming that it is a material issue for all steel producers.

The CSRD and ESRS require climate disclosures on topics of interest to investors as identified under the Taskforce for Climate-Related Financial Disclosure (TCFD) – governance, strategy, risk management, metrics and targets. The Steel Climate Standard requires disclosure of a subset of this information, which includes:

- Metrics such as the company average steel emissions intensity (CASEI),

- Targets defined as science-based emission targets (SBETs), and

- Strategies to achieve the SBETs.

The EUDR entered into force on June 29, 2023, and is intended to limit the EU market’s impact on global deforestation, forest degradation and biodiversity. It covers seven commodities, including timber, and many products derived from them. The EUDR establishes criteria to ensure that the commodities and products in the EU market are deforestation-free (have not been produced on land that was deforested/degraded after December 31, 2020) and were legally produced (in accordance with applicable laws in country of origin). The Steel Climate Standard considers the use of bio-based materials as a viable decarbonization strategy and also recognizes that those materials must be sustainably sourced. To that end, the Standard establishes its own criteria for sustainably sourced bio-based materials as outlined in Section 6.2.

The EU CBAM mandates international suppliers of steel and steel products intended for import into the EU to disclose the emissions of these products for purposes of charging a tariff that is assessed based on the product’s emissions intensity. The policy is intended to level the playing field for European steel producers required to comply with the EU Emissions Trading System (ETS) by up-charging imported products that have higher embodied carbon. The CBAM’s carbon accounting boundary has significant differences from the Steel Climate Standard, namely that several categories of a steel producer’s Scope 3 emissions are not included. Nevertheless, the Steel Climate Standard was presented to policymakers to help guide their plans for CBAM implementation and can be a vehicle for declarations of certified emissions intensity data.

The Steel Climate Standard has also been presented to policymakers deliberating border carbon measures in other markets, including the United Kingdom and the United States.

The Steel Climate Standard is a global standard. It has been developed through a partnership and collaboration of steel companies, recyclers, steel associations, supply chain partners and a wide array of stakeholders from around the world. The GSCC® is a coalition of these partners headquartered in numerous countries around the world and which have operations in more than 80 countries. The steel industry needs to reduce carbon emissions everywhere, and this Standard provides a pathway toward that goal.

The GSCC® is an original signatory of the Steel Standards Principles, a partnership with steel producers, trade associations, standards-setting bodies and other stakeholders under the leadership of the World Trade Organization and Worldsteel Association. There is a growing body of work uniquely focused on carbon accounting, measurement and decarbonization strategies for the steel sector, and the Steel Standards Principles provides a collaborative framework to create the conditions for the interoperability of these programs, driving more opportunity for lowering steel emissions and to facilitate trade of low carbon steel and steel products.