The Steel Climate Standard

Framework for Steel Product Certification and Corporate Science-Based Emissions Targets

1 Our Mission

- Provide a single, technology-agnostic framework for steel product certification and company science-based emissions target-setting that applies to all steel producers equally on a global basis;

- Allow all steel customers to know the carbon emissions associated with the steel products they are purchasing; and

- Create an industry standard for achieving the emissions reduction goals in the Paris Climate Agreement by 2050.

The world needs steel. Steel is an essential engineering material for the global economy. It is a critical material used to manufacture our vehicles and machinery, construct our buildings and factories, produce our energy, and much more. Steel is also playing a central role in the transition to a greener economy with the production of electric vehicles, wind turbines, solar arrays, and other clean tech products. Steel is fundamental for advancing a circular economy because its many different applications and components can efficiently be recycled, reused and remanufactured.

The world needs to lower greenhouse gas (GHG) emissions. The GSCC® is leading the charge to reduce greenhouse gas emissions and encourage investments in lower emissions technology as part of the global effort to decarbonize economies and societies. An October 2022 report by the United Nations shows that countries are not on track to limit carbon emissions to 1.5° C by the end of the century1. Steel producers around the world are at different stages in their efforts to reduce emissions and achieve sustainable production.

We already have the technology. Steelmakers have become more efficient and producing a tonne of steel today requires only 40% of the energy it did in 1960. Many steelmakers around the world have successfully converted steel production processes to maximize steel's circularity, resulting in lower carbon intensity products. This means that the technologies already exist to cut global steelmaking emissions by over 70%. And new technologies are on the horizon that will reduce emissions even further.

We need a global standard. Customers need to know the GHG emissions intensity of the steel they are purchasing to meet their company's ambitions related to decarbonization. Numerous groups and companies — including the GSCC® — are advocating for a global standard to measure and report carbon emissions from steel. Today, some steelmakers and organizations are advocating for a common standard that features a "ferrous scrap sliding scale" relative to use of scrap steel for setting carbon reduction trajectories. This approach sets two disparate standards for emissions from steel producers; one standard for steel made from iron ore extractive production processes, and another for steel made from circular electric arc furnace (EAF) processes. This method is unacceptable when a common sector goal for the steel industry is sought to achieve the 1.5-degree Celsius (°C) objective by 2050.

Having a dual standard that allows higher-emission steelmakers to postpone changing their production process to readily available, less carbon intensive methods conflicts with the basic objective of 2050 goal setting. Higher-emitting steel producers use the dual standard to claim their steel products are "green" even if they are produced with significantly higher carbon emissions than those using the electric arc furnace (EAF) process. The GSCC®'s mission is to lead the way toward a truly effective low-emission steel standard for all producers that accurately counts carbon emissions — regardless of the production methods.

The GSCC® Steel Climate Standard is designed to incentivize true decarbonization of the steel sector by providing carbon intensity standards for global trade purposes as well as a science-based emissions target setting process that ensures companies are managing emissions on a trajectory to attain the 1.5° C scenario by 2050.

We must avoid a standard that enables greenwashing. Creating a standard based on a ferrous scrap sliding scale could result in higher emissions steel products being labeled as "green" and prioritized at the expense of lower emissions steel products. This will discourage innovation and allow higher emissions steelmakers to postpone making changes in their production process. Even worse, it will lead to higher GHG emissions overall from the steel sector. A truly effective lower-carbon steel standard must be one in which actual, attained carbon emissions are measured, and the standard must apply equally to all producers on a global basis.

We can accomplish this. The standard must lead to the global steel industry significantly reducing carbon emissions. This can be achieved by creating a science-based emissions standard based on actual emissions that would apply to all producers equally on a global basis. Establishing a standard should incentivize actions that will generate decreases in carbon emissions to achieve the 1.5° C science-based emissions target for the global steel sector.

In summary, the Steel Climate Standard will:

- Establish a single set of process-agnostic product standards and require steel manufacturers to establish science-based emission targets. This approach will promote the global use of advanced technologies in steel production on a more expeditious timeline to achieve the 1.5° C science-based emissions target for the global steel sector.

- Allow global steel producers and consumers to benchmark against a single common standard, provide transparency for consumers when making lower-carbon emissions steel product purchasing decisions, and provide a known and replicable method to track, plan, and implement carbon emissions reduction activities.

For more information, please see https://globalsteelclimatecouncil.org/

2 Overview of Standard

With the Steel Climate Standard, the GSCC® seeks to provide a set of technology-agnostic standards which accelerate the transition to lower-carbon steel and incentivize the industry to achieve lower carbon emissions by 2050 in alignment with the 1.5° C scenario for the steel sector. In doing so, the Steel Climate Standard's protocol is comprised of two main components:

- Product certification criteria for lower-carbon emission steel;

- Science-based emissions target setting criteria for steel producers.

Setting science-based emissions targets as outlined by the Steel Climate Standard is a requirement. However, certifying steel products is optional.

The Steel Climate Standard's established boundary includes critical activities that are excluded from other standards, such as scrap collection and processing as well as hot rolling. Finally, the Steel Climate Standard considers all relevant GHG pollutants (not just CO₂) and requires independent third-party verification of emissions calculations and reduction targets. In developing this standard, the GSCC® has set out to establish a simple and straightforward, yet comprehensive, science-based steel climate program.

This standard document uses the term "shall" to indicate the requirements to be met if a company is certifying its products or establishing science-based emissions targets in alignment with the Steel Climate Standard. The term "may" is used when describing what is allowable under the standard, but is not necessarily required.

2.1 Guiding Principles

The primary objective of the GSCC® is to establish a Steel Climate Standard, focusing on the following guiding principles:

- Reducing GHG emissions from the global steel industry;

- Establishing a standard that is technology/production method agnostic;

- Establishing a standard with a system boundary that includes all relevant GHG pollutants from Scope 1, Scope 2 and Scope 3 emissions;

- Establishing a standard that aligns with a science-based glidepath to achieve a 1.5° C scenario by the year 2050;

- Requiring third-party verification of emissions data and science-based emissions targets; and

- Providing relevant information on sustainable steelmaking to appropriate decision makers.

The GSCC® has used these guiding principles to build a framework for a proposed standard with five key pillars as its foundation (see Figure 2-1).

These pillars represent the key characteristics of the Steel Climate Standard, and are further described as follows:

Scientific. In developing the proposed standard, the GSCC® has relied upon extensive research and information compiled from the latest climate science, steel-industry data, and market projections from creditable sources such as the Intergovernmental Panel on Climate Change (IPCC), International Energy Agency (IEA), and World Steel Association (WSA). Our objective is to ensure that the proposed standard aligns with the latest climate science and Paris Agreement goals to achieve sector-wide targeted reductions by 2050.

Quantitative. The Steel Climate Standard specifies numeric steel product carbon emissions intensity standards, based on clearly defined boundaries that include all relevant carbon-intensive processes in the steelmaking value chain. These intensity standards reduce over time to achieve the decarbonization goal for the global steel industry by 2050.

Comprehensive. The standard establishes a holistic decarbonization program that includes product-based standards as well as a framework for setting science-based emissions targets for steel producers, both of which rely on the reduction of carbon emissions intensity on a carbon dioxide equivalent (CO₂e) basis, inclusive of all relevant GHGs. This product-focused approach allows for decarbonization to be practically achieved on a mill-by-mill basis, as technology evolves over the next few decades.

Principled. The Steel Climate Standard is founded on a clear vision for the future of steel in a decarbonizing economy based on a process-agnostic approach. By eliminating the “sliding scale” concept for ferrous scrap, the Steel Climate Standard holds all steel manufacturers to the same Steel Climate Standard. This approach recognizes the steel manufacturers that have already made significant investments in lower carbon technology and provides market drivers for near-term reductions from the highest emitting sources as well as long-term investment in emerging technology needed to meet the ultimate decarbonization goal in 2050.

Transparent. The framework developed by the GSCC® seeks to simplify and provide a straightforward process for certification of products, verification of science-based emissions targets, and labeling for consumer/end-market use. The Steel Climate Standard establishes a clearly defined and comprehensive set of criteria by which progress in decarbonizing the steel sector can be measured. It relies on global standards to quality assure and verify product intensity claims.

2.2 Key Concepts

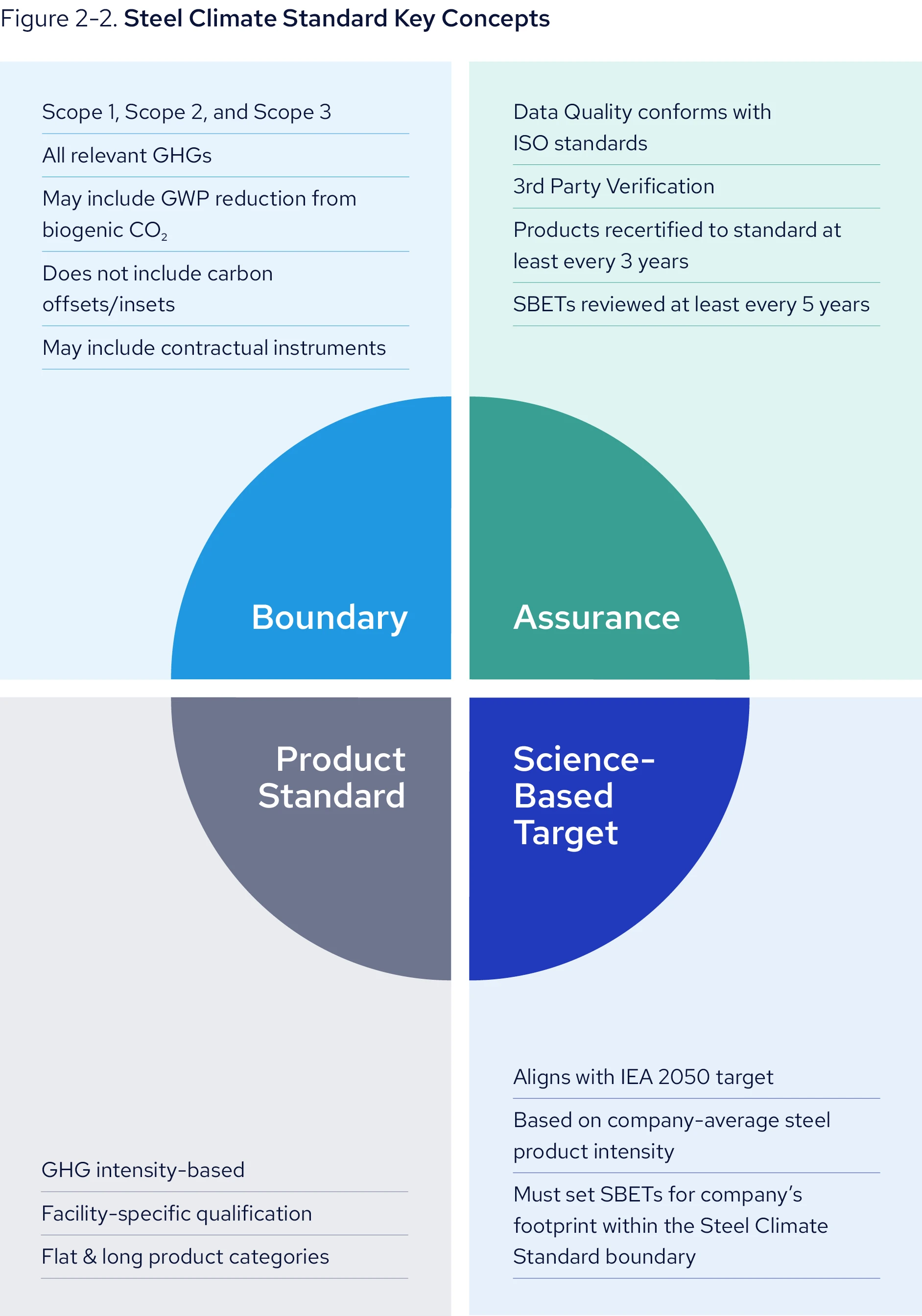

The GSCC®'s overarching vision for the proposed standard is a comprehensive process-agnostic decarbonization framework that is focused on global participation in the steel sector to lower overall GHG emissions by 2050. This approach encourages all steel producers to converge toward a common goal. The Steel Climate Standard framework is built on four key concepts as summarized in Figure 2-2.

Boundary. The Steel Climate Standard defines a clear boundary for Scope 1, Scope 2, and Scope 3 sources and includes applicable GHG pollutants. The Steel Climate Standard boundary will cover activities from mining to hot rolling and may include contractual instruments for renewable energy and Renewable Thermal Certificates (RTCs). Emissions reductions from biogenic CO₂ and the use of process off-gases recovered for reheating and to generate electricity may be included. Carbon offsets and insets shall be excluded.

Assurance. The Steel Climate Standard protocol requires minimum data quality criteria in accordance with ISO standards for developing the carbon footprint. Within the established boundary, companies will calculate an intensity metric in units of tonnes of CO₂e per tonne of hot rolled steel (t CO₂e/t hot rolled steel). Independent third-party verification of all data in accordance with established ISO standards is required.

Product Certifications. The Steel Climate Standard provides a concise set of criteria for evaluating and certifying flat and long steel products as lower-carbon emissions steel based on their carbon intensity as determined above. Companies can certify as many or as few products as desired and can seek certification at the facility level. The product standard defines and promotes best practices for labeling of certified lower-carbon steel products to provide transparency for consumers/end-market use. Labels shall adhere to a standard format that identifies the GSCC® Steel Climate Standard.

Science-Based Emissions Targets. The Steel Climate Standard approach champions science-based emissions targets as a key pillar of a company’s transition to a lower-carbon economy. Participating companies are required to establish and assure climate targets that are based on sound science, in alignment with the 1.5° C scenario and IEA projections for 2050, and that are then reevaluated at least every 5 years.

3 Steel Climate Standard Product Certification

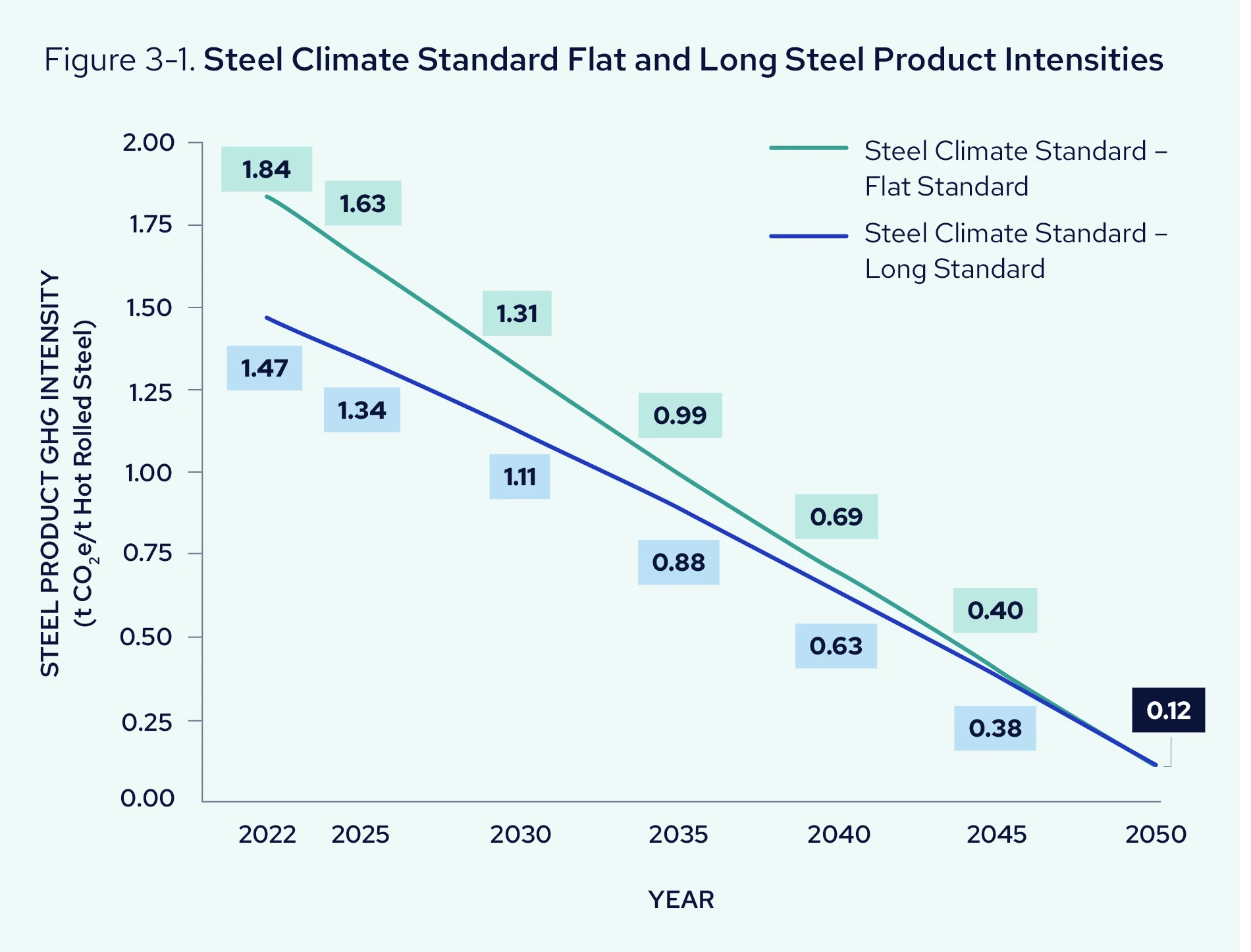

These standards have been developed in alignment with the Steel Climate Standard Steel Sector Decarbonization Glidepath described in Appendix C. The GSCC® will reevaluate this glidepath at least every five years to ensure that it reflects the latest climate science, at which point the product standards may be adjusted if needed to remain aligned with a revised glidepath.

3.1 Demonstrating Conformance

A company’s conformance with the long and flat product certification criteria shall be demonstrated by calculating a steel product’s GHG emissions intensity, in t CO₂e/t hot rolled steel, as outlined in Section 4. The GHG emissions intensity shall be calculated for a given product based on facility-specific product value chain data from the most recent full year.

In addition, since conformance with the standard follows a product life cycle accounting approach, a subset of a given product produced at a single facility may be certified to the Steel Climate Standard product standards. For example, a company may produce two “grades” of a steel product at a single mill — one of which is manufactured specifically to achieve a lower product intensity (e.g., through the procurement of renewable energy contractual instruments). As long as the company can demonstrate that it meets all requirements for product emissions accounting for the particular grade of product produced at the mill, it can be certified to the Steel Climate Standard.

Companies who wish to adopt the Steel Climate Standard product standards shall establish and publicly disclose SBETs as outlined in Section 5 within two years of joining the GSCC®’s Steel Climate Standard as a condition of their participation in the program.

3.2 Certification & Labeling of Products

To initially certify products under the Steel Climate Standard, companies shall:

- Provide the steel product’s GHG intensity value and documentation of third-party verification of the steel product intensity emissions calculations (t CO₂e/t hot rolled steel) as outlined in Section 4; and

- Establish SBETs in accordance with Section 5 within two years of joining the GSCC®’s Steel Climate Standard.

The steel product’s GHG intensity value may be documented and verified via an environmental product declaration (EPD) as long as the life cycle assessment (LCA) covers all sources within the Steel Climate Standard boundaries and conforms with the product calculation guidelines in Section 4. Since the Steel Climate Standard product standards decrease annually and the data required to calculate the steel product GHG intensity is collected for the most recent complete year, the intensity value shall be compared to the Steel Climate Standard for the year corresponding to the data collected. That is, if a company wishes to obtain Steel Climate Standard certification for a certain product in 2024, the data collected relative to the value chain for that product shall be for the year 2023, and the resulting product GHG intensity value shall be compared to the 2023 Steel Climate Standard product standard value.

The steel product GHG intensity value provided to the GSCC® shall be facility-specific. Once the GSCC® has determined that a product meets the standard, a product certification will be issued and will be valid for up to three years. To maintain this certification, the company shall calculate and self-declare annual product intensity values for the most recent year to the GSCC®. The annual product intensity values shall be compared to the Steel Climate Standard value for the corresponding year to demonstrate that the product continues to meet the standard. The product intensity values shall be third-party verified every three years during revalidation.

If the GSCC® revises the standard during its periodic review cycle, the company will need to recertify against the revised standard in order to continue use of the GSCC® Steel Climate Standard certification for the product.

The GSCC® will provide product labeling templates to participating companies for optional use in marketing/labeling certified products at the company’s discretion. Additionally, the GSCC® will maintain a list of certified products on its website.

3.3 GSCC® Process for Certifying to Product Standards

The overall process for certifying products to the GSCC® Steel Climate Standard is presented in Figure 3-2 below.

4 Emissions Accounting for Products

4.1 Product GHG Boundaries

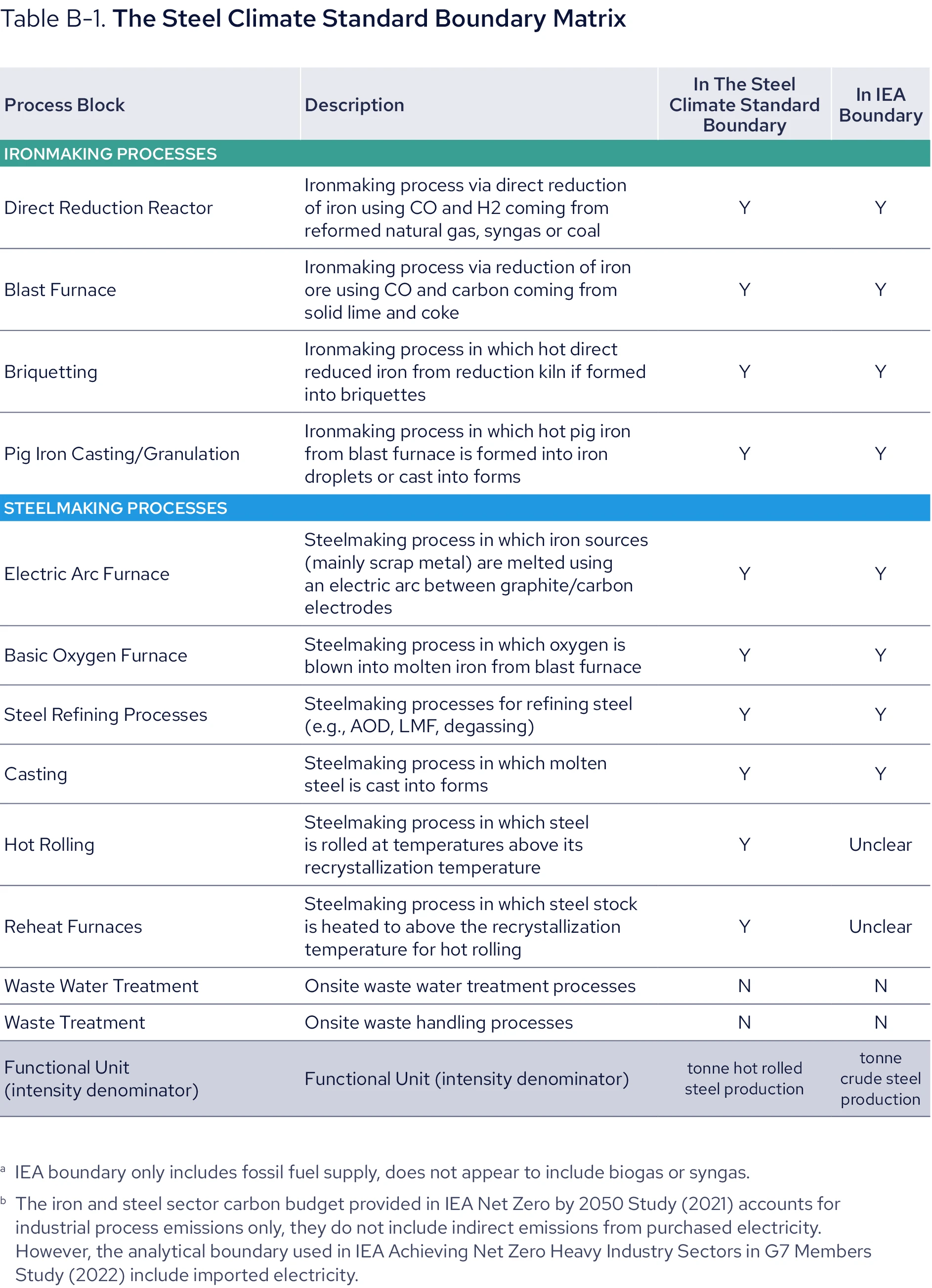

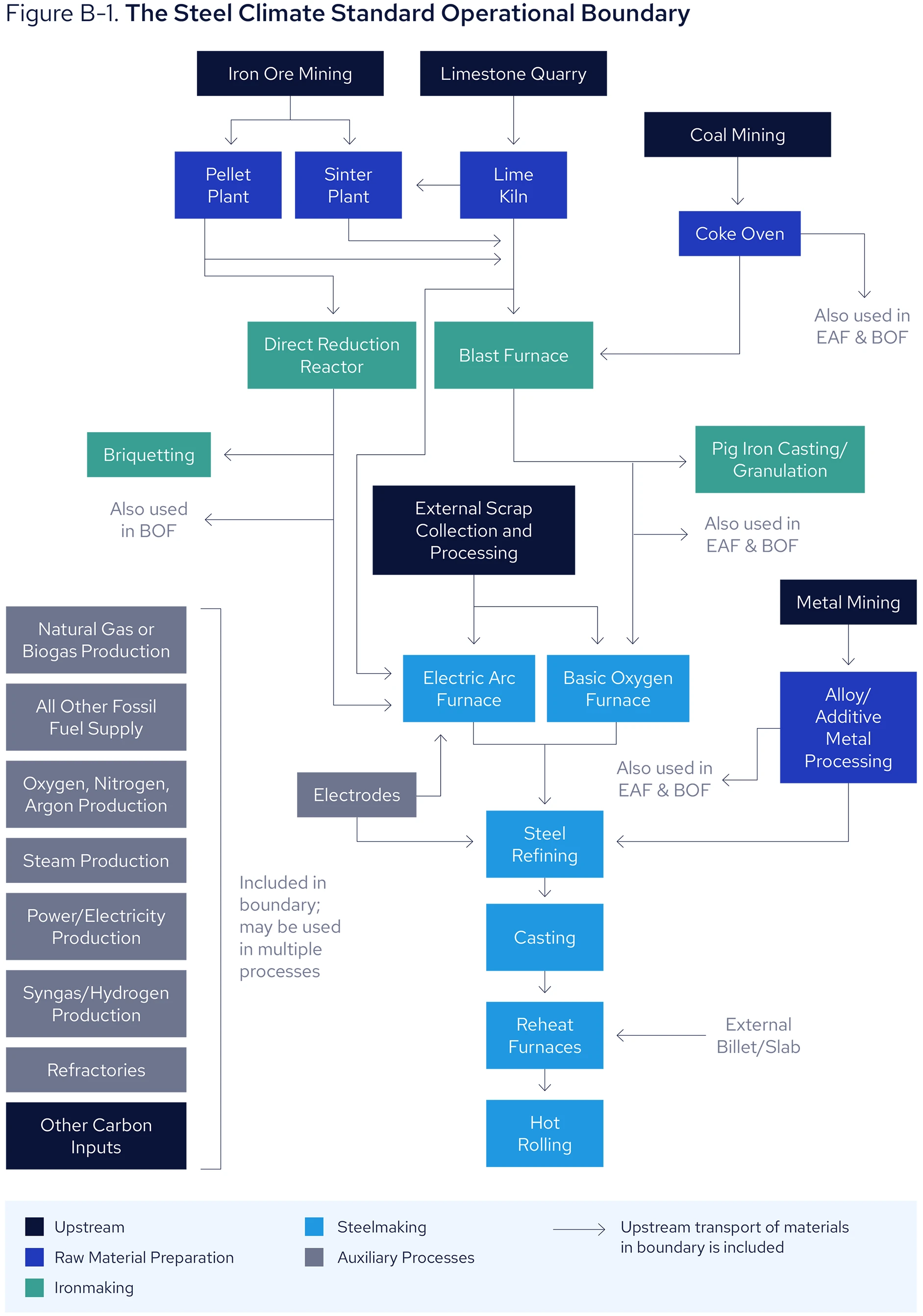

To certify a steel product to the Steel Climate Standard product standards, cradle-to-gate product life cycle emissions that consider all processes identified within the Steel Climate Standard fixed operational boundary (see Figure B-1), shall be determined on a facility basis and expressed as the product’s hot rolled steel emissions intensity (t CO₂e/t hot rolled steel). The calculation of the product’s GHG intensity shall be based on global standards and guidance related to product life cycle GHG accounting and reporting as outlined in the following sections.

4.2 Product Life Cycle Emissions

In determining a steel product’s cradle-to-gate life cycle emissions to determine conformance with the Steel Climate Standard product standards, the embodied carbon values shall be developed in conformance with the following global standards and guidance:

- GHG Protocol Product Life Cycle Accounting and Reporting Standard

- ISO 14040:2006, Environmental management — Life cycle assessment — Principles and framework

- ISO 14044:2006, Environmental management — Life cycle assessment — Requirements and guidelines

- ISO 14067:2018, Greenhouse gases — Carbon footprint of products — Requirements and guidelines for quantification

The following requirements also apply to the calculation of a steel product’s GHG emissions intensity:

- Carbon offsets and insets shall not be included.

- Biogenic carbon uptake and emissions from the use of sustainably sourced materials (See Appendix F Section F.2) shall be accounted for separately from fossil-based carbon in conformance with ISO 14067:2018.

- Emissions reductions due to the procurement of RTCs meeting the quality criteria in Appendix F Section F.2 may be accounted for in determining the direct emissions due to the steel product’s manufacture. Emissions associated with RTCs shall be reported separately.

- The life cycle GHG emissions associated with steelmaking shall not be allocated between steel products and co-products (e.g., slag). Similarly, avoided emissions associated with the use of co-products in place of other products outside of the Steel Climate Standard boundary (e.g., due to the use of slag in production of cement) shall not be used as an emissions reduction. The only exception to this pertains to process off-gases which are recovered and used for reheating or power generation as discussed in Appendix F.

- Emissions reductions due to the procurement of contractual instruments such RECs, PPAs, VPPA and green tariffs meeting the quality criteria in Appendix F Section F.3 may be accounted for in determining the indirect emissions due to electricity used for the steel product’s manufacture. Emissions associated with these contractual instruments shall be reported separately.

- Primary data which conforms with the requirements in Appendix F Section F.4 shall be used for both activity data as well as for emission factors, if available.

- Use of primary data for purchased billets and slabs used to manufacture the steel product is required.

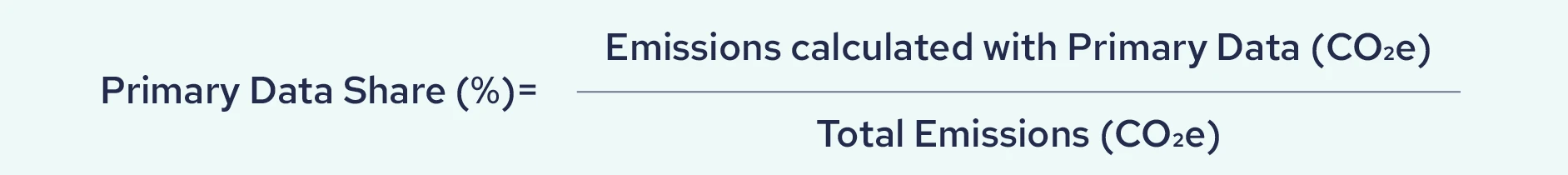

- In the absence of primary data for emission factors, industry average data may be used, and its sources shall be referenced. In addition, if secondary data is used for emission factors, then the share of primary data used to calculate the product’s hot rolled steel emissions intensity shall be calculated and reported as follows:

4.3 Product Emissions Certification Criteria

The data used for the determination of the product-level GHG emissions intensity based on the Steel Climate Standard boundary for hot rolled steel production shall be independently verified in conformance with the requirements of recognized international verification standards such as ISO 14064-3:2019, Greenhouse gases — Part 3: Specification with guidance for the verification and validation of greenhouse gas statements as it applies to product GHG statements. This verification may be to either the ‘reasonable level of assurance’ or the ‘limited level of assurance’. Alternatively, the steel product’s GHG intensity value may be documented and verified via an EPD in conformance with ISO 14025:2006, Environmental labels and declarations — Type III environmental declarations — Principles and procedures as long as the LCA covers all sources within the Steel Climate Standard boundaries and conforms with the product calculation guidelines in this section.

The GSCC® has issued a Technical Support Document which establishes criteria for qualifying third party verifiers. Adherence to the requirements in the Technical Support Document ensures that the companies and individuals providing third-party verification have demonstrated a specified level of technical proficiency necessary to assess the accuracy of steel product GHG emission intensity calculations as outlined in this standard. A list of approved verifiers will be provided on the GSCC® website.

5 Steel Climate Standard Science-Based Emissions Target Setting

5.1 Guidelines for Setting Science-Based Emissions Targets (SBETs)

To establish SBETs, a participating company shall follow the steps outlined below.

Step 1. Calculate Base Year CASEI

As a first step in the target setting process, a company shall calculate the base year Company-Average Steel Emissions Intensity (CASEI) for its steelmaking operations expressed as t CO₂e/t hot rolled steel. The CASEI is calculated as outlined in the accounting procedures prescribed in Section 6. The base year is comprised of a full year of representative operations and shall be no earlier than five years before the year during which a company establishes the SBET.

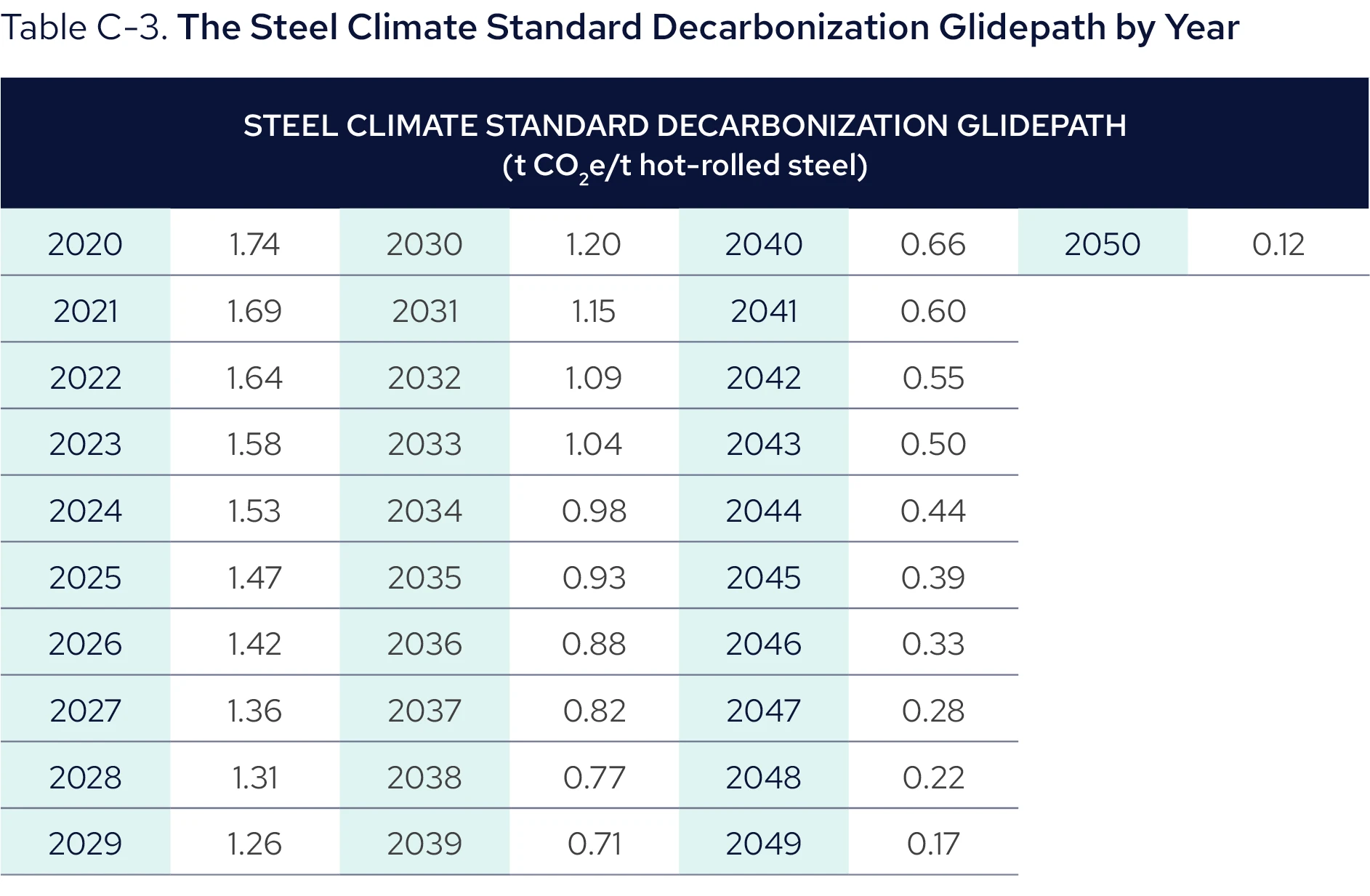

Step 2. Compare the Base Year CASEI to the Steel Climate Standard Decarbonization Glidepath

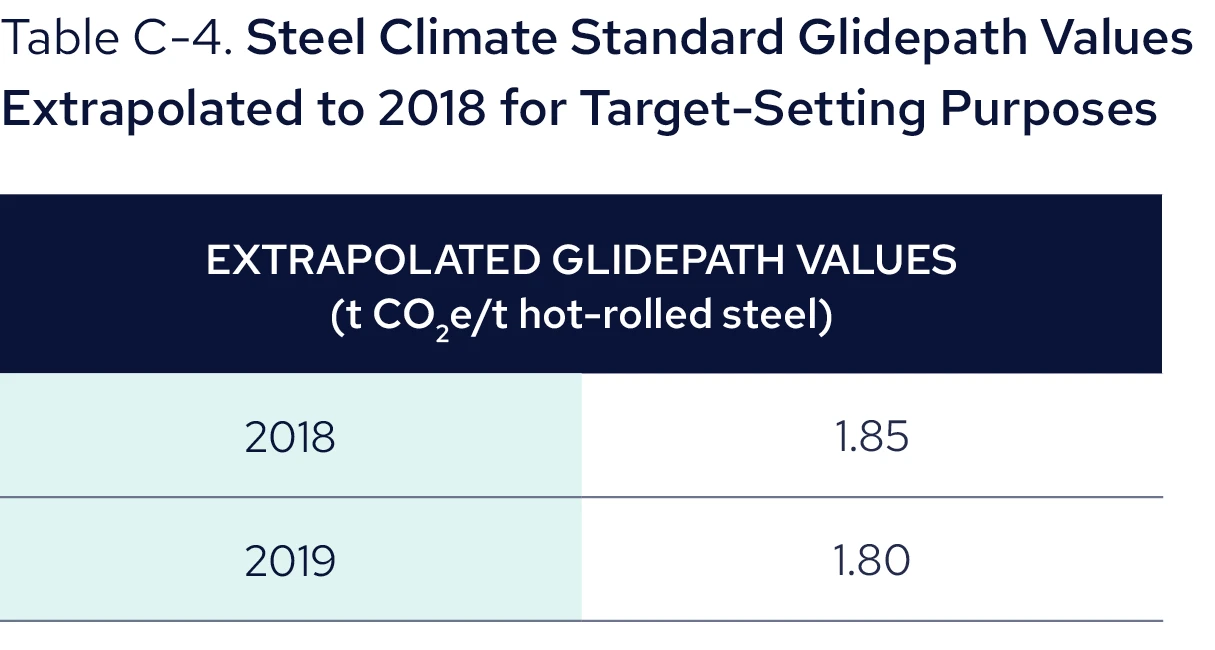

Once the base year CASEI is calculated, the company shall compare it to the Steel Climate Standard Decarbonization Glidepath value in Appendix Table C-3 for the year that corresponds to the base year selected by the company. For companies electing to use a base year that is prior to 2020, the Steel Climate Standard Decarbonization Glidepath is extrapolated back to 2018 in Appendix Table C-4 for reference in this step of target-setting.

The company shall develop a company specific GHG reduction trajectory that results in the reduction of its CASEI to align with the Steel Climate Standard Decarbonization Glidepath. If the base year CASEI is above the Steel Climate Standard Decarbonization Glidepath, the company shall develop its company specific GHG reduction trajectory as indicated in Step 3A. If the base year CASEI is below the Steel Climate Standard Decarbonization Glidepath, the company shall develop its company specific GHG reduction trajectory as indicated in Step 3B.

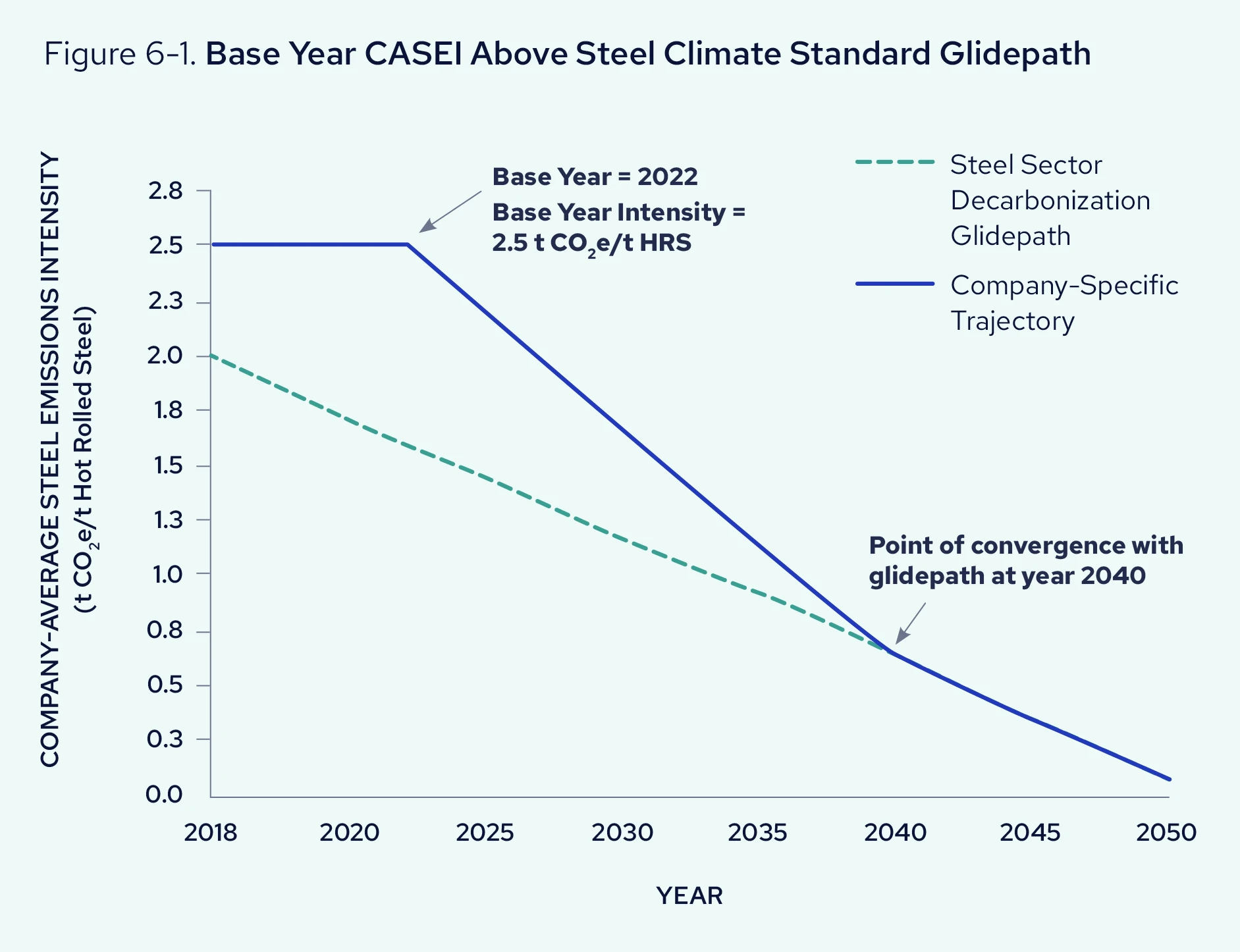

Step 3A. If the Base Year CASEI is ABOVE the Steel Climate Standard Decarbonization Glidepath

If the comparison in Step 2 shows that the base year CASEI value is above the Steel Climate Standard Decarbonization Glidepath value for the corresponding year, then the company will draw a line from its base year CASEI value to the point of convergence with the Steel Climate Standard Decarbonization Glidepath at the year 2040. The trajectory of that line, from the base year CASEI value to the point of intersection and then continuing along the Steel Climate Standard Decarbonization Glidepath to 2050, represents the minimum intensity reduction progress that must be achieved to meet the Steel Climate Standard’s science-based target criteria. Refer to Figure 6-1 for an illustrative example (Example 1) of this scenario.

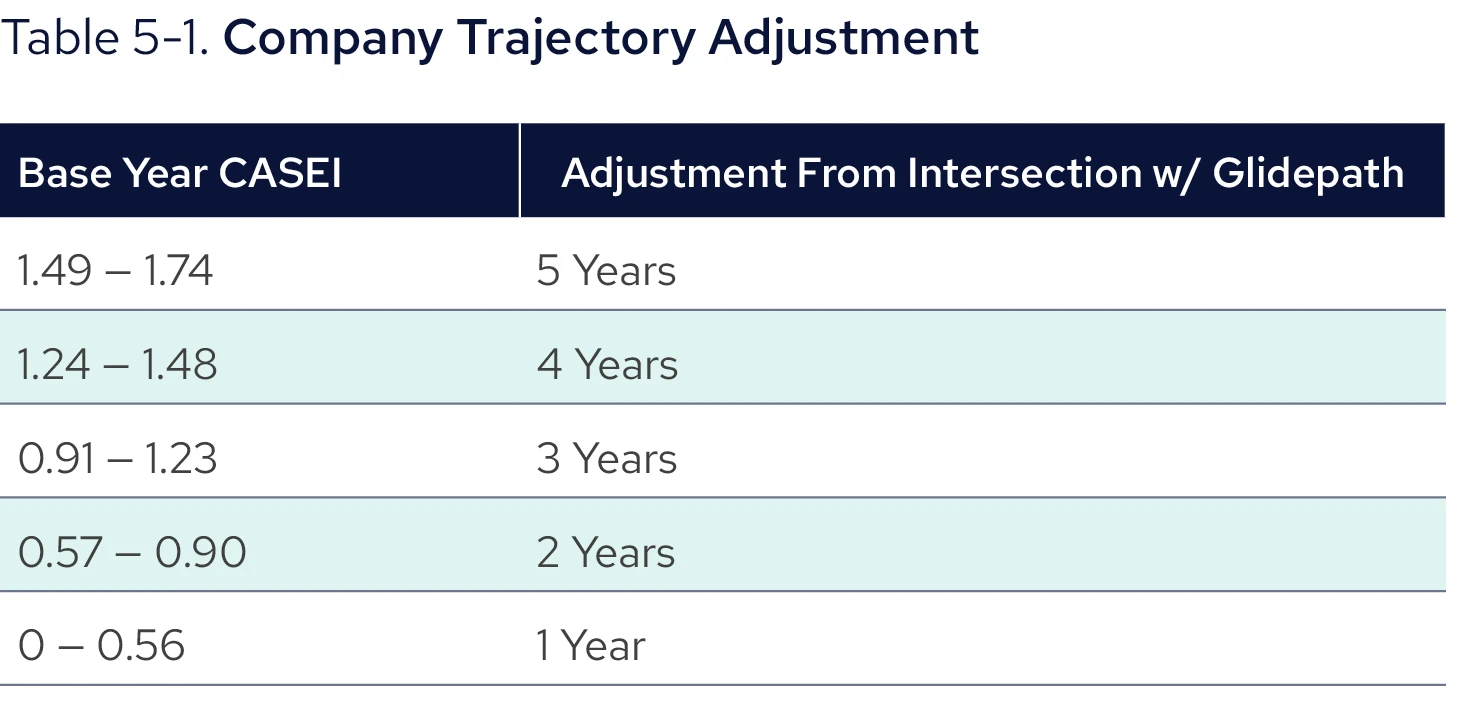

Step 3B. If the Base Year CASEI is BELOW the Steel Climate Standard Decarbonization Glidepath

If the comparison in Step 2 shows that the base year CASEI value is below the Steel Climate Standard Decarbonization Glidepath value for the corresponding year, then the company will draw a horizontal line from its base year CASEI value to the point of convergence with the Steel Climate Standard Decarbonization Glidepath. The company will then determine the year represented by that point of convergence and draw a second line from its base year CASEI value to the point on the Steel Climate Standard Decarbonization Glidepath that is 1-5 years ahead of the point of convergence, depending on the company’s base year CASEI, as indicated in Table 5-1 below. This approach recognizes companies that have already made progress in decarbonizing their operations while still challenging them to continue to lower their emissions.

The resulting trajectory, from the base year to the intensity corresponding to that 1-5 year point and then continuing along the Steel Climate Standard Decarbonization Glidepath

to 2050, represents the minimum intensity reduction progress that must be achieved to meet the Steel Climate Standard science-based target criteria. Refer to Figure 6-2 for an illustrative example (Example 2) of this scenario.

Step 4. Set Interim SBETs

The company shall establish an interim SBET, or series of interim SBETs, to be met within 5-10 years from the base year. The interim SBETs shall be set at or below the company specific trajectory determined as outlined above. Once the company specific trajectory intersects with the Steel Climate Standard Decarbonization Glidepath in a given year, the company’s SBETs shall continue to align with (i.e., be at or below) the Steel Climate Standard Decarbonization Glidepath to 2050. The SBETs shall be supported by a credible, documented company-level strategy for reducing GHG emissions from steelmaking operations and the expected timeline for implementing changes to operations within The Steel Climate Standard boundary to achieve real reductions in its CASEI.

Step 5. Set Long-Term SBET

Each company shall set a long-term SBET, for a year from 2040 to 2050 which is at or below its company-specific trajectory.

5.2 Certification Requirements for Targets

A company’s base year CASEI calculation and its interim and long-term SBETs shall be independently verified by a third party. The verifier shall also ensure that target setting conforms with the steps outlined above prior to the commitment date. Once its SBETs are made public, the company shall track its performance by calculating and self-declaring its CASEI annually.

A company’s strategy for achievement of its SBETs and its progress toward meeting those targets shall be disclosed publicly, for example, as part of the Corporate Sustainability Report (CSR) or via reporting through a carbon disclosure framework. Progress shall be determined based on the general trend in the company’s CASEI as well as overall activities aimed at reducing emissions. That is, progress shall not be strictly based on the CASEI decreasing measurably each year, recognizing that there may be extenuating circumstances in certain years that result in no decrease from the previous year. For example, projects involving implementation of abatement or other decarbonization strategies may span over multiple years before measurable reductions are fully realized. The company’s CASEI shall be third-party verified at least every five years.

A company shall recalculate the base year CASEI and re-establish targets if there is a significant change that would materially impact relevance of the target to the company’s operations (e.g., changes in company structure due to acquisitions/divestments, discovery of a material error in underlying calculations, etc.). The GSCC® suggests that such a change be considered significant if it results in a 10% or greater change in the company’s CASEI. Finally, should the GSCC®’s periodic review of the decarbonization glidepath result in an adjustment to the glidepath, SBETs shall be reviewed and revised/revalidated, as necessary.

5.3 Steel Climate Standard Process for Setting Science-Based Emissions Targets

The overall process for establishing company SBETs is presented in Figure 5-1 below.

6 Emissions Accounting for Targets

6.1 Target Boundaries

For the purposes of establishing SBETs, The Steel Climate Standard’s fixed operational boundary requires steel manufacturers to include all in-boundary processes and GHGs as prescribed in Appendix B, regardless of whether they fall within the company’s Scope 1, Scope 2 or Scope 3 GHG emissions, as defined by the GHG Protocol Corporate Reporting and Accounting Standard. The calculations of these emissions shall be based on global standards and guidance related to corporate-level GHG accounting and reporting as outlined in the following sections.

6.2 Scope 1 Emissions

Scope 1 (direct) GHG emissions from all steel-making processes that are under operational control of the company and are within the Steel Climate Standard operational boundary (see Figure B-1) shall be counted in calculating hot rolled steel GHG emissions intensity. In determining Scope 1 GHG emissions, calculations shall be developed in conformance with the following global standards and guidance:

- GHG Protocol Corporate Accounting and Reporting Standard

- ISO 14064-1:2018, Greenhouse Gases — Part 1: Specification With Guidance At The Organization Level For Quantification And Reporting Of Greenhouse Gas Emissions And Removals

The Steel Climate Standard seeks to incentivize the reduction of direct process emissions from the iron and steel sector, hence companies shall not account for purchased carbon offsets in calculating Scope 1 emissions. Carbon insets, which typically involve the implementation of nature-based carbon sinks onsite, shall also be excluded when calculating Scope 1 emissions. Similarly, carbon sequestration associated with land-use, whether on- or off-site, shall be excluded.

The Steel Climate Standard considers the use of bio-based materials as a viable decarbonization strategy for steelmaking. Biocarbon derived from biomass produced from the following materials shall be considered sustainably sourced:

- Materials conforming to a third-party controlled sourcing certification (e.g., Forest Stewardship Council (FSC) Controlled Wood, Sustainable Forest Initiative (SFI) Certified Sourcing or Fiber Sourcing, Programme for the Endorsement of Forest Certification (PEFC) Controlled Sources, Sustainable Biomass Program Controlled); and/or

- Materials considered eligible sources of supply according to the Green-e Framework for Renewable Energy Certification, Version 1.0 (2017), Green-e regional standards; and/or

- (3) Relevant products complying with the EU Deforestation Regulation (EUDR) (June 2023) imported into or out of the European Union.

If the bio-based materials meet the above quality criteria, then the biogenic CO₂ emissions from the use of those materials may be excluded up to 100% from the calculation of Scope 1 emissions, if duly justified, and shall be reported as a separate line item in the steel company’s GHG accounting.

The Steel Climate Standard also recognizes that process off-gases (e.g., coke oven gas, blast furnace gas, etc.) have fuel value and are commonly recovered to minimize/avoid flaring and for use as fuels in lieu of natural gas. Most process off-gases are used within the Steel Climate Standard boundary (as fuel for boilers, heaters, reheat furnaces, or for electricity generated to support steelmaking operations), but some may also be used outside the Steel Climate Standard boundary (as fuel for downstream annealing or tempering furnaces, or for exported electricity generation). When these process off-gases are used within the boundary, the company’s calculated direct GHG emissions will inherently reflect this use. However, in cases where process off-gases are being used outside the boundary to displace other fossil fuels (e.g., natural gas), the Steel Climate Standard allows for the calculation of an emissions credit using a system expansion approach. In such cases, the credit shall be equal to the difference between the emissions associated with the use of the process off-gases and the emissions that would have resulted from the use of the identified fuel that it replaced (e.g., natural gas). The calculated credit may then be excluded from Scope 1 emissions and shall be reported as a separate line item in the steel company’s GHG accounting.

Finally, natural gas use can be a significant source of Scope 1 emissions in steel making. The Steel Climate Standard recognizes the developing market for renewable thermal certificates (RTCs) as a way to incentivize the replacement of fossil-based natural gas with renewable natural gas (RNG), similar to how such contractual instruments incentivized the development of renewable energy. Therefore, RTCs may be used in accounting for Scope 1 emissions. Specifically, RTCs are a means of accounting for the environmental attributes and GHG reductions associated with renewable natural gas, which for Scope 1 purposes is the emission of biogenic CO₂ from the combustion of RNG. Hence, RTCs may only be used as a credit against CO₂ emissions from natural gas combustion.

The RTCs shall meet the following criteria adapted based on the ISO 14064-1:2018 criteria for contractual instruments until specific criteria is published to validate the environmental attributes (specifically, validate carbon values to support carbon reduction claims) of RTCs via an internationally recognized standard or guidance.

- RTC shall convey the information associated with the unit of biomethane (one dekatherm) delivered together with the characteristics of its production;

- RTC is ensured with a unique claim;

- RTC is tracked and redeemed, retired, or cancelled by or on behalf of the reporting entity;

- RTC is as close as possible to the period to which the contractual instrument is applied and comprises a corresponding timespan;

- RTC is produced within the country, or within the market boundaries where consumption occurs.

Emission reductions associated with the procurement of RTCs shall be reported as a separate line item in the steel company’s GHG accounting.

6.3 Scope 2 Emissions

Scope 2 (indirect) emissions from the generation of electricity, steam, heat, or cooling acquired and consumed by the steel company shall be counted in calculating hot rolled steel GHG emissions intensity. In determining Scope 2 GHG emissions, calculations shall be developed in conformance with the following global standards and guidance:

- GHG Protocol Corporate Accounting and Reporting Standard

- ISO 14064-1:2018, Greenhouse Gases — Part 1: Specification With Guidance At The Organization Level For Quantification And Reporting Of Greenhouse Gas Emissions And Removals

Scope 2 GHG emissions from purchased electricity shall be determined in conformance with the requirements of ISO 14064-1:2018 Annex E.2 Treatment of Imported Electricity.

In some cases, the steel company may be exporting process off-gases that are used to generate electricity, which can then be re-imported for use in steelmaking operations. In cases where the company is a net exporter of the off-gas produced electricity (i.e., it does not re-import all electricity generated from the off-gas it produces), the Steel Climate Standard allows for an emissions credit using a system expansion approach. The credit is calculated as the difference between the emission factor to produce electricity using the off-gas and the emission factor of the electricity displaced. The calculated emissions for the displaced electricity shall be based on the local grid emission factor, using primary data sources. Contractual instruments to cover any portion of electricity used on-site or exported that is generated from process off-gases shall not be used.

When a company is using contractual instruments for the procurement of renewable electricity, as defined in Appendix A, the contractual instruments shall meet the following quality criteria of ISO 14064-1:2018, E.2.2 Additional Information:

- Conveys the information associated with the unit of electricity delivered together with the characteristics of the generator;

- Is ensured with a unique claim;

- Is tracked and redeemed, retired, or cancelled by or on behalf of the reporting entity;

- Is as close as possible to the period to which the contractual instrument is applied and comprises a corresponding timespan;

- Is produced within the country, or within the market boundaries where consumption occurs if the grid is interconnected.

Emission reductions associated with the procurement of contractual instruments shall be reported as a separate line item in the steel company’s GHG accounting.

If a company is not using contractual instruments and market-based information is not available, residual grid mix factors shall be used for the year being reported (or the most recent year available). A location-based approach using average grid emission factors shall only be used when market-based and residual mix data is unavailable.

6.4 Scope 3 Emissions

Scope 3 (indirect) GHG emissions from all supply chain processes and activities that are considered within The Steel Climate Standard operational boundary (see Figure B-1) but are not covered under Scope 1 and Scope 2 shall be counted as Scope 3 in calculating hot rolled steel GHG emission intensity.

In determining Scope 3 GHG emissions, the embodied carbon values shall be developed in conformance with the following global standards and guidance:

- GHG Protocol Corporate Accounting and Reporting Standard

- GHG Protocol Corporate Value Chain (Scope 3) Accounting and Reporting Standard12

- GHG Protocol Technical Guidance for Calculating Scope 3 Emissions (Version 1.0)13

The steel company shall use primary data provided by the supplier, if available, provided it conforms to the following requirements:

- The declared embodied GHG value has been determined by the supplier for the material in conformance with the requirements outlined by the Steel Climate Standard herein for determining product-life cycle emissions (See Appendix E);

- The declared embodied GHG value is cradle-to-gate;

- The declared embodied GHG value has been third party verified in conformance with the international standards referenced in Appendix E, as applicable.

If primary data is not available for the determination of Scope 3 emissions, the steel company shall use industry average data (secondary data) and reference its source. If a steel company is purchasing billets and slabs to produce certain products, then the use of primary supplier data is required for those materials.

While the embodied carbon associated with scrap is considered to be zero, Scope 3 emissions associated with the collection and processing of scrap shall be accounted for, as that is within the Steel Climate Standard boundary.

6.5 Company-Average Steel Emissions Intensity (CASEI)

For target-setting purposes, a company’s Scope 1, Scope 2 and Scope 3 GHG emissions from the operations that are included in The Steel Climate Standard boundary shall be addressed. A company may use either the operational or financial control approach in alignment with the GHG Protocol. The basis for target setting will be a company-average steel emissions intensity (CASEI) calculated as follows:

- Calculate the Scope 1, Scope 2 and Scope 3 emissions as tonnes CO₂e in a given year based on the Steel Climate Standard GHG and operational boundaries for hot rolled steel production as outlined above for each facility owned and operated by the company.

- Calculate the weighted average across all facilities on a per tonne hot rolled steel basis to determine the CASEI.

The determination of the CASEI for the target base year (and subsequent verification years as required) shall be independently verified in conformance with the requirements of recognized international verification standards such as ISO 14064-3:2019, Greenhouse gases — Part 3: Specification with guidance for the verification and validation of greenhouse gas statements as it applies to organization GHG statements. This verification may be to either the ‘reasonable level of assurance’ or the ‘limited level of assurance’.

The GSCC® will develop a separate guidance document to establish criteria for qualifying third party verifiers. This purpose of this guidance will be to ensure that the companies and individuals providing third-party verification have demonstrated a specified level of technical proficiency necessary to assess the accuracy of steel product GHG emissions intensity calculations as outlined in this standard. A list of approved verifiers will be provided on the GSCC® website.

6.6 Target Setting Boundary Examples

The following examples are provided to illustrate how target boundaries shall be applied.

Example #1: Company A purchases billets from Company B, which is an independent third party (i.e., Company A has no operational or financial control over Company B). Company A manufactures hot rolled product from the billets it purchases, which are then marketed and sold under Company A’s product portfolio. In this example, the upstream Scope 3 emissions associated with Company B’s production of the billets purchased by Company A shall be included in the boundary for Company A’s SBET. Company A shall use primary data for the Scope 3 emissions associated with the purchased billet.

Example #2: Company A produces pig iron, which is used in its steel-making facilities across the company. A portion of the pig iron that Company A produces is sold to Company C, which is an independent third-party steel manufacturer (neither company has operational or financial control over the other). In this example, the downstream Scope 3 emissions and the resulting amount of hot rolled product associated with Company C’s production of hot rolled steel from the pig iron supplied by Company A is still considered within the boundary and shall be included in the calculation for Company A’s SBET. Company A shall use primary data for the Scope 3 emissions associated with the steel manufacturing by Company C, if available. Otherwise, secondary data (e.g., industry average factors) may be used.

Example #3: Company A produces hot rolled steel products from billets that it makes internally at its steel-making operations. However. Company A makes more billets than it has the capacity to roll into product. Therefore, Company A has a financial arrangement with Company D, which is a toll manufacturing agreement. Under this agreement, Company D agrees to hot roll a portion of the billets that Company A makes into products per Company A’s specification. The final products are sold to customers under Company A’s product portfolio. In this example, the downstream Scope 3 emissions associated with Company D’s production of hot rolled steel from the billets supplied by Company A is considered within the boundary and shall be included in the calculation for Company A’s SBET. Company A shall use primary data for the Scope 3 emissions associated with the hot rolling performed by Company D if available. Otherwise, secondary data (e.g., industry average factors) may be used.

6.7 Company-Specific Trajectory Examples

Examples illustrating how companies shall develop company-specific trajectories to support SBET-setting are provided in this section.

Example 1: Base year CASEI value is ABOVE the Steel Climate Standard Decarbonization Glidepath: In this example, the company has chosen a base year of 2022, and its CASEI in that year is 2.5 t CO₂e/t hot rolled steel. Therefore, it is above the 2022 Steel Climate Standard Decarbonization Glidepath value of 1.64 t CO₂e/t hot rolled steel. To determine the company-specific GHG decarbonization trajectory, a line is drawn from the base year CASEI value to the Steel Climate Standard Decarbonization Glidepath value in 2040, as depicted by the green line in Figure 6-1. This green line represents the minimum linear GHG intensity reduction progress required by the Steel Climate Standard.

Example 2: Base year CASEI value is BELOW the Steel Climate Standard Decarbonization Glidepath: In this example, the company has chosen a base year of 2022, and its CASEI in 2022 is 1.4 t CO₂e/t hot rolled steel. Therefore, it is below the 2022 Steel Climate Standard Decarbonization Glidepath value of 1.64 t CO₂e/t hot rolled steel. To determine the company-specific GHG decarbonization trajectory, a horizontal line is drawn from the base year CASEI value to the point of convergence with the Steel Climate Standard Decarbonization Glidepath (in this case, in the year 2027, as depicted by Point A in Figure 6-2). According to Table 5-1, if the base year CASEI is between 1.24 and 1.48, then the target shall be adjusted by four years (as depicted by Point B in Figure 6-2). Then a line is drawn from the base year CASEI to Point B, where it converges with the Steel Climate Standard Decarbonization Glidepath. This green line represents the minimum linear GHG intensity reduction progress required by the Steel Climate Standard for the company specific GHG reduction trajectory.

Appendix A. Glossary of Terms

Base Year: The year selected as the reference for comparing changes in GHG emissions over time. For the GSCC®’s Steel Climate Standard, a company’s base year can be no earlier than five years before the year during which the SBET is established.

By-Product: For the purposes of the Steel Climate Standard, by-product is defined as material produced incidentally as an unintended, secondary result of the production of a primary product. By-products are typically lower in both volume and value relative to co-products. Examples of by-products for iron- and steel-making processes may include flue or baghouse dust, mill scale, tailings, and other materials that are sent off site for recycling or reuse. This may or may not align with regulatory definitions of local jurisdictions.

Carbon Dioxide Equivalent (CO₂e): Unit for comparing the radiative forcing of a GHG to carbon dioxide using its pollutant-specific global warming potential (GWP). For the purposes of this standard, CO₂e has shall be calculated as outlined in Appendix B.

Carbon Inset: An action or activity, which a company implements internally, that indirectly reduces a company’s carbon footprint outside of its direct operations but within its own supply chain (e.g., planting trees as nature-based carbon sink onsite).

Carbon Intensity: The amount of carbon emissions per unit of product. For the purposes of this standard, carbon intensity is defined as the tonnes of CO₂e emitted per tonne of hot rolled steel produced (t CO₂e/t hot rolled steel).

Carbon Offset: An action or activity, which is implemented external to a company’s value chain, that compensates for the company’s own GHG emissions (e.g., purchasing offsets generated by nature-based carbon sink located off site).

Co-Product: For the purposes of the Steel Climate Standard, co-product is defined as material produced in parallel to, or as a consequence of, the production of a primary product and for which there is significant volume and potential commercial value. Examples of co-products for iron- and steel-making processes may include slag, blast furnace gas, and other materials that are sent off site for sale or processing in other end markets. This may or may not align with regulatory definitions of local jurisdictions.

Company-Average Steel Emissions Intensity (CASEI): GHG emissions intensity (in units of tonnes of CO₂e emitted per tonne of hot rolled steel produced) calculated as a weighted average across all steel products and all steel making operations within the Steel Climate Standard defined boundary.

Contractual Instruments for Renewable Energy: Any type of contract between two parties for the sale and purchase of renewable energy that are either bundled with environmental attributes about the energy generation, or are unbundled attribute claims. For the purposes of the Steel Climate Standard, contractual instruments will be recognized if they are verifiable in accordance with local requirements. Markets differ as to what contractual instruments are commonly available or used by companies to purchase energy or claim specific attributes about it, but they can include energy attribute certificates, RECs, GOs/REGOs, PPAs, green energy certificates, supplier specific emission rates, etc.

Cradle-to-Gate: Life cycle of emissions and removals attributable to a product from material acquisition (including extraction, transportation, and processing/manufacturing of raw materials) through the point at which the product leaves the reporting company’s gate (e.g., immediately following the product’s production).

Crude Steel: Steel in the first solid state after melting, suitable for further processing or for sale (also referred to as raw steel). This is typically measured at the point at which continuous casting or ingot casting has been completed, and prior to any further processing such as roughing or hot rolling.

Embodied Carbon: GHG emissions associated with a product’s life cycle, including raw material extraction, transportation, processing, and manufacturing.

Energy Attribute Certificate: A category of contractual instrument that represents certain information or attributes about the energy generated (technology type, nameplate capacity, location, etc.) but does not represent the energy itself. This category includes a variety of instruments with different names, including certificates, tags, credits, or generator declarations (for example, Renewable Energy Certificates or RECs in the U.S.). The Steel Climate Standard recognizes verifiable renewable energy certificates used in accordance with local legislation as long as they meet the quality criteria of ISO 14064-1:2018, E.2.2 Additional Information.

Flat steel products: Category of steel products characterized by their wide and thin shape produced by passing steel ingots or slabs through rollers. Flat products include sheet, strip, coil, welded tube and plate products.

Greenhouse Gas (GHG): Gaseous constituent of the atmosphere, both natural and anthropogenic, that absorbs and emits radiation at specific wavelengths within the spectrum of infrared radiation emitted by the Earth’s surface, the atmosphere and clouds. For the purposes of the Steel Climate Standard, GHGs include carbon dioxide (CO₂) methane (CH₄), nitrous oxide (N₂O), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), sulfur hexafluoride (SF₆) and nitrogen trifluoride (NF₃). An individual GHG shall be considered insignificant if it represents less than 0.5% of total Scope 1 GHG emissions, and less than 5% of total Scope 3 emissions within The Steel Climate Standard boundary, on a CO₂e basis.

High Alloy Specialty Steel: Steel with alloy content greater than or equal to 8 wt. % and less than 10.5% chromium.

Hot Rolled Steel: Steel product that has been heated above the recrystallization temperature and is then plastically deformed in the working or rolling operation. This process is used to create shapes with the desired geometrical dimensions and material properties while maintaining the same volume of metal.

Life Cycle Assessment: Compilation and evaluation of inputs, outputs, and potential environmental impacts of a product system throughout its lifecycle.

Location-Based Method: A method to quantify Scope 2 GHG emissions based on average energy generation emission factors for defined locations, including local, subnational, or national boundaries.

Long steel products: Category of steel products characterized by their length and relatively small cross-sectional area, typically produced from blooms or billets into straight lengths. Long products include bars, rods, structural steel beams and shapes, rail, wires, and specialty steel sections.

Market-Based Method: A method to quantify Scope 2 GHG emissions based on GHG emissions emitted by the generators from which the reporter purchases electricity through contractual instruments (including bundled and unbundled attributes) on their own.

Operational Boundary: Defines the scope of direct and indirect emissions for processes/operations that fall within the established organizational boundary. For The Steel Climate Standard program, this is a fixed boundary that begins with upstream production and transportation of alloys/feedstocks (including scrap collection, processing, and transport) and ending with hot rolling of steel product as identified in Appendix Table B-1.

Primary Data: Primary data are the data collected from specific processes and activities in a product’s life cycle. Primary activity data may be obtained through meter readings, purchase records, utility bills, engineering models, direct monitoring, mass balance, stoichiometry, or other methods for obtaining data from specific activities in the company’s value chain. Primary data may also include data provided by suppliers or other value chain partners related to specific activities in a product’s value chain.

Product Category: A group of steel products that can fulfill equivalent functions. For the purposes of the Steel Climate Standard product standards, this is defined as flat products and long products. See Appendix D for detailed categorization of steel products.

Reheat Furnace: Steelmaking process in which steel stock is heated above the recrystallization temperature for the purpose of hot rolling.

Renewable Natural Gas: A mixture of methane and carbon dioxide (and other hydrocarbons) produced from the biological decomposition of organic materials which has been upgraded to meet pipeline quality standards so that it may blend with, or substitute for, geologic natural gas.

Renewable Thermal Certificate (RTC): A unique representation of the environmental attributes associated with the production of renewable natural gas. One certificate is created in association with the generation of one dekatherm of renewable natural gas.

Residual Grid Mix: The energy mix which represents the emissions and generation remaining after certificates, contracts, and supplier-specific factors have been claimed and. Residual mix factors are the preferred market-based default emission factors for any of an organization’s electricity for which it cannot apply contractual instruments. The use of the residual mix emission factors avoids double-counting of the emissions attributes of contractual instruments.

Science-Based Emissions Target (SBET): Under the Steel Climate Standard program, SBETs are GHG emissions reduction targets that are in line with the goals of the Paris Agreement to limit global warming to 1.5° C above pre-industrial levels. By definition, SBETs are based on sound science and a credible feasibility estimate of what the company can achieve by a specified target date.

Scope 1 Emissions: Direct GHG emissions resulting from the activities owned or controlled by a company, including emissions from on-site fuel consumption.

Scope 2 Emissions: Indirect GHG emissions which result from the generation of electricity, heating, cooling, and/or steam that is consumed (i.e., purchased or otherwise imported).

Scope 3 Emissions: Indirect GHG emissions associated with the activities that are not owned of controlled by a company, but that are a consequence of its activities.

Scrap: Iron, steel and other metal material in metallic form that is recovered in multiple life cycle stages, including steel production processes (typically referred to as “home scrap”), the manufacturing processes of final products (typically referred to as “prompt scrap”, “new scrap” or “preconsumer scrap”) and the end of life of final products (typically referred to as “obsolete scrap”, “old scrap” or “postconsumer scrap”), and is recycled as a raw material for steel production.

Scrap Processing: The various steps and activities associated with the preparation of scrap metal as an input material to steelmaking, which may include but is not limited to sorting, separating, mixing, blending, baling, pressing, crushing, briquetting, shearing, and shredding.

Secondary Data: Process data that are not from specific processes in the studied product’s life cycle and do not qualify as primary data. Secondary data can come from external sources or other internal sources that serve as proxy for the studied process. Examples of sources of secondary data include: financial data, average usage factors or emission factors from life cycle databases, industry average emission factors, company process activity data, etc.

Stainless Steel: Steel with greater than 10.5% chromium content.

Steel Product: A product designed and manufactured from steel that is marketed and sold to customers.

Third Party: A fully independent and approved or accredited certification body that has provided assurance that specific criteria as defined by the standard have been met.

Toll Processing or Manufacturing: Outsourcing all or part of the processing or manufacturing of a product to a third party where a steel company provides the raw materials or semi-finished products as well as the final product specifications. This includes re-rollers within the Steel Climate Standard boundary.

Tonne: Metric tonne (t), equivalent to 1,000 kilograms or 2,204.6 pounds (lbs) or 1.1023 short tons.

Waste: For the purposes of the Steel Climate Standard, waste is defined generally as unusable material produced incidentally as an unintended result of the production of a primary product. Examples of wastes for iron- and steel-making processes may include dust, sludge, tailings, and other materials that are sent off site for disposal. This may or may not align with regulatory definitions of local jurisdictions.

Appendix B. Steel Climate Standard Boundary

The Steel Climate Standard is establishing a system boundary for determining steel’s carbon intensity that captures the key sources of direct and indirect GHG emissions in the steel manufacturing value chain. It is important to establish a comprehensive and consistent boundary to ensure that:

- Reduction targets cover all relevant, carbon-intensive processes (ironmaking and steelmaking processes, as well as critical upstream raw material processes), and

- Comparisons between product carbon intensities are on a like-for-like basis.

The Steel Climate Standard boundary is fixed, meaning that reporting companies shall include all sources identified as “in boundary” in the calculation of steel product carbon intensity, regardless of whether they are Scope 1, Scope 2 or Scope 3. For example, if a company purchases billet or slab to make its hot rolled steel product, the upstream Scope 3 emissions associated with the processes in the Steel Climate Standard boundary involved in making that billet or slab are counted. This ensures that the billet or slab is sourced responsibly and prevents artificial reductions in intensity. Similarly, if a company transfers billet or slab to a third party for hot rolling of their product under a toll manufacturing agreement, the downstream Scope 3 emissions associated with that hot rolling activity are counted. This ensures that a company does not outsource hot rolling activities to artificially reduce their intensity.

The following sections provide more detailed information regarding the key boundary definitions established under the Steel Climate Standard program.

B.1 Steel Climate Standard GHG Boundary Definition

The calculation of emissions for purposes of the Steel Climate Standard program shall account for the GHGs required by the Kyoto Protocol and The GHG Protocol Corporate Accounting and Reporting Standard (revised edition, 2015).2 These GHGs are currently: carbon dioxide (CO₂), methane (CH₄), nitrous oxide (N₂O), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs) sulfur hexafluoride (SF₆) and nitrogen trifluoride (NF₃). An individual GHG shall be considered insignificant if it represents less than 0.5% of total Scope 1 GHG emissions, and less than 5% of total Scope 3 emissions within the Steel Climate Standard boundary, on a CO₂e basis.

Total GHG emissions shall be calculated in terms of carbon dioxide equivalents (CO₂e) using the 100-year global warming potential (GWP) published by the IPCC. GSCC® encourages use of GWP values available from the latest IPCC assessment report (AR). Per ISO 14064-1:2018, if the GWP values are not taken from the latest IPCC report, the emissions factors or the database reference used in the calculation, as well as their source, shall be provided for purposes of 3rd party verification

B.2 Steel Climate Standard Operational Boundary Definition

The Steel Climate Standard operational boundary is shown in Figure B 1. It is identical to the boundary identified by the IEA in its analytical boundary for defining lower carbon steel production, with several key exceptions:3

- It extends beyond the steel casting step to include reheat furnaces and hot rolling processes, which can be energy-intensive;4

- It includes upstream processes for collecting and processing ferrous scrap; and

- It includes upstream production of metal alloys and metal additives (e.g., de-oxidizing agents) that may be significant for certain products.

Since the operational boundary ends with hot rolling, the denominator for steel product carbon intensity is tonne hot rolled steel production. Table B-1 provides a more detailed description of the processes considered within the Steel Climate Standard operational boundary and also compares it to the analytical boundaries used by IEA in developing their iron and steel sector decarbonization pathway discussed in Appendix C.

Note: This diagram represents current understanding of the relevant processes considered to be within the Steel Climate Standard Boundary and shall be included regardless of whether they are Scope 1, Scope 2 or Scope 3. Any intermediate steps not specifically shown shall be included.

Appendix C. Steel Climate Standard Decarbonization Glidepath

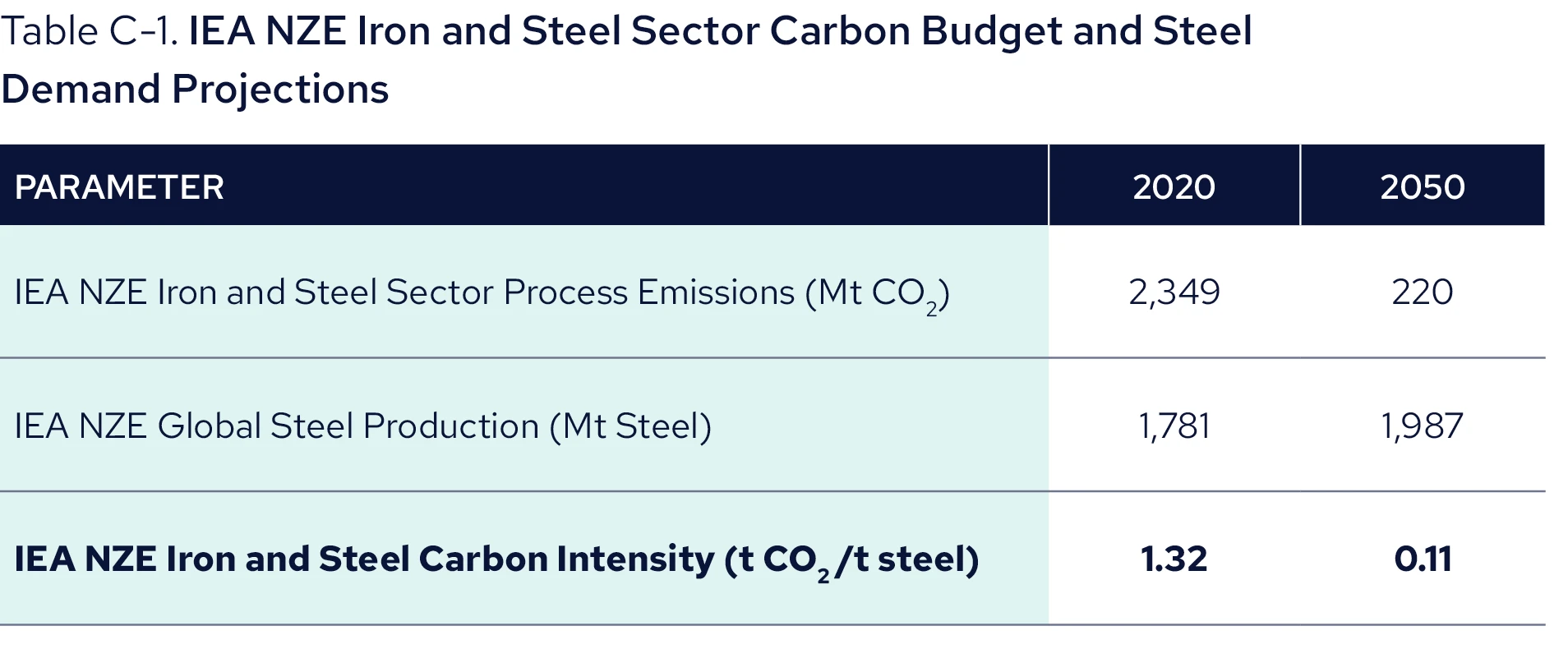

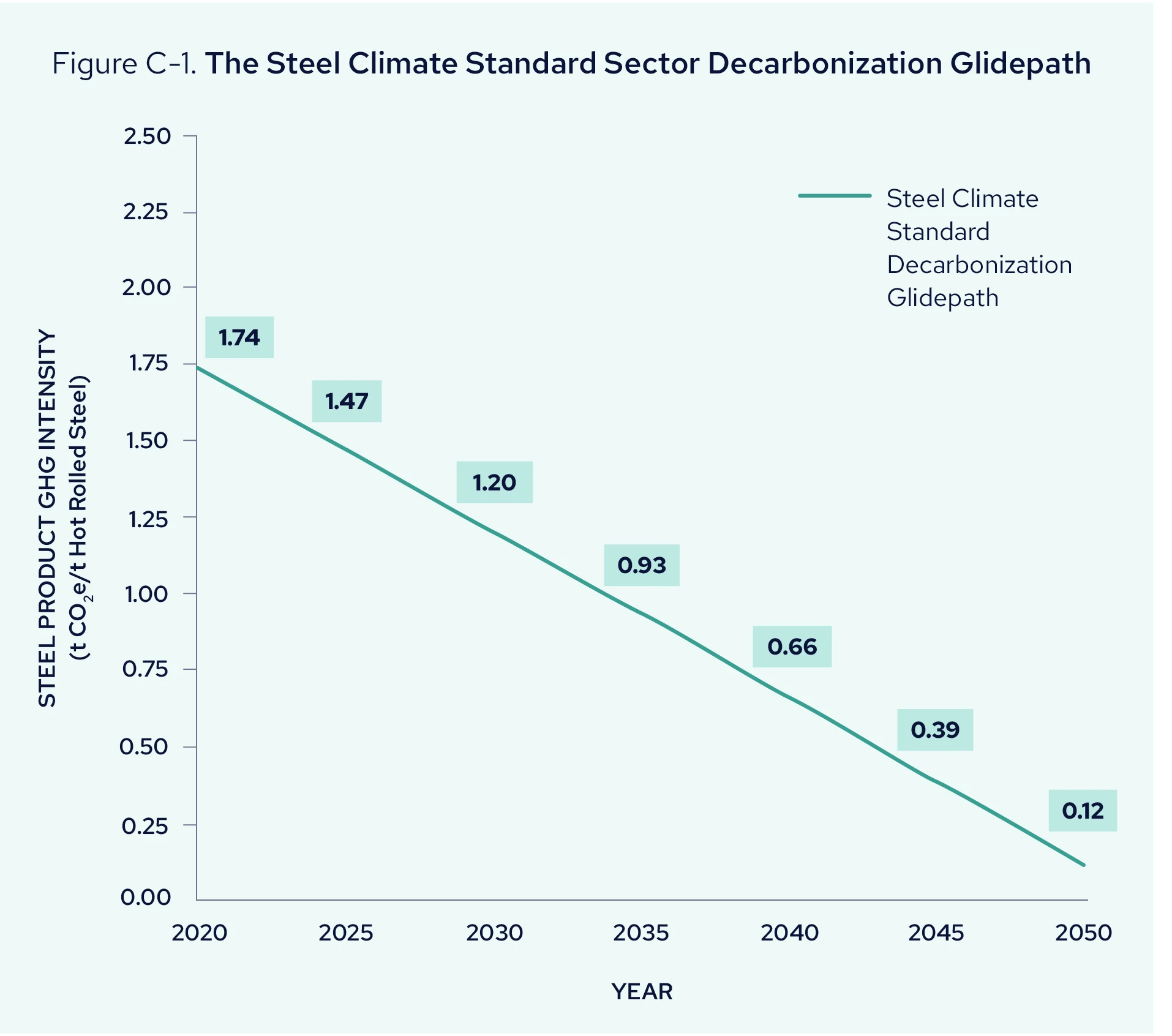

The Steel Climate Standard product intensity standards and company science-based target setting goals are based on Net Zero by 2050: A Roadmap for the Global Energy System (IEA NZE), published by the IEA, which provides a global pathway to achieve net zero CO₂ emissions by 2050.5 The IEA NZE allocates a carbon budget for the iron and steel industry that is used as the basis for Steel Climate Standard’s Decarbonization Glidepath. The IEA NZE pathway projects global CO₂ emissions from the iron & steel industry decreasing from 2,349 million tonnes in 2020 to 220 million tonnes in 2050. According to the IEA NZE, steel demand is projected to increase by 12% by 2050. Based on these values, the IEA’s projected steel product direct emissions intensity (in t CO₂/t crude steel) is calculated for 2020 and 2050 as shown in Table C-1.

The values shown in Table C-1 account for industrial process emissions only. They do not account for indirect emissions from electricity use by the iron and steel industry sector because IEA NZE attributes all such emissions to the power sector. In order to add indirect emissions from electricity use by the iron and steel sector to the IEA NZE projections shown in Table C-1, the Steel Climate Standard adopts the adjustment made by the Science-Based Target Initiative (SBTi) and Rocky Mountain Institute (RMI) to estimate indirect emissions from electricity use by the iron and steel industry for 2020 and 2050.6, 7 The estimated Scope 2 emissions intensity values for the iron and steel sector in 2020 and 2050, as well as the total intensity are provided in Table C-2.

The IEA NZE iron and steel sector carbon budget was derived based on various assumptions and projections regarding the expected evolution and adoption of low carbon technologies and mitigation strategies over the next three decades across the sector globally, as outlined in their 2020 study.8 Given the many complex variables and inherent uncertainty in such an analysis, it is practically impossible to predict the timing and effectiveness of the emerging technological innovations for this sector over the next 30 years. Furthermore, as stated previously, the GSCC® believes that sector decarbonization should be pursued on a process-agnostic basis where progress is not dependent on specific steel-making technologies. Therefore, the Steel Climate Standard Decarbonization Glidepath begins at the IEA’s sector-specific carbon budget in 2020 and ends at the IEA’s sector-specific carbon budget in 2050 to achieve net zero, and assumes a constant rate of decline (i.e., a straight line) between 2020 and 2050.

It should be noted that the IEA’s emissions scope only considered carbon dioxide emissions for the iron and steel sector processes included in its analytical boundary (IEA, 2022), with the exception of fossil fuel supply, for which methane emissions were also considered. In order to fully account for the sector’s footprint, the Steel Climate Standard considers all relevant GHGs on a CO₂e basis within its operational boundary as defined in Appendix B Section B.1. Furthermore, as indicated in Appendix B Section B.2, the analytical boundary as outlined by IEA (2022) excludes a number of iron and steel value chain processes that are included in the Steel Climate Standard operational boundary. Hence, while the numeric values adopted by the Steel Climate Standard are based on IEA’s chosen emissions and operational boundaries, the units of measure are revised from t CO₂/t crude steel to t CO₂e/t hot rolled steel for the Steel Climate Standard Decarbonization Glidepath. This approach adds a level of conservatism, resulting in more ambitious steel sector intensity targets. The values in Table C-3 are based on a constant rate of decline from 2020 to 2050 to create the Steel Climate Standard Decarbonization Glidepath shown in Figure C 1.

The GSCC® will review this glidepath at least every five years and may revise it in future years to align with the latest climate science, advancements in low carbon technology and its deployment within the sector, and updated steel industry production.

In order to allow for establishing a company-specific trajectory starting from a base year that is up to five years before the year during which a company establishes the SBET, the Steel Climate Standard Decarbonization Glidepath values are extrapolated back to 2018 in Table C-4 below.

Appendix D. Basis for Steel Climate Standard Product Standards

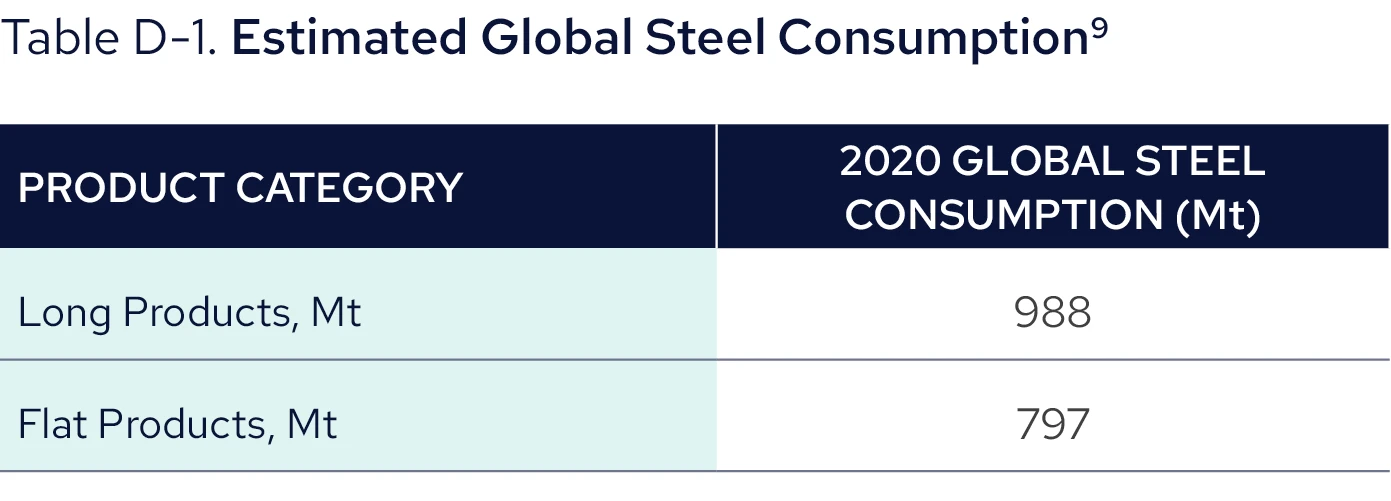

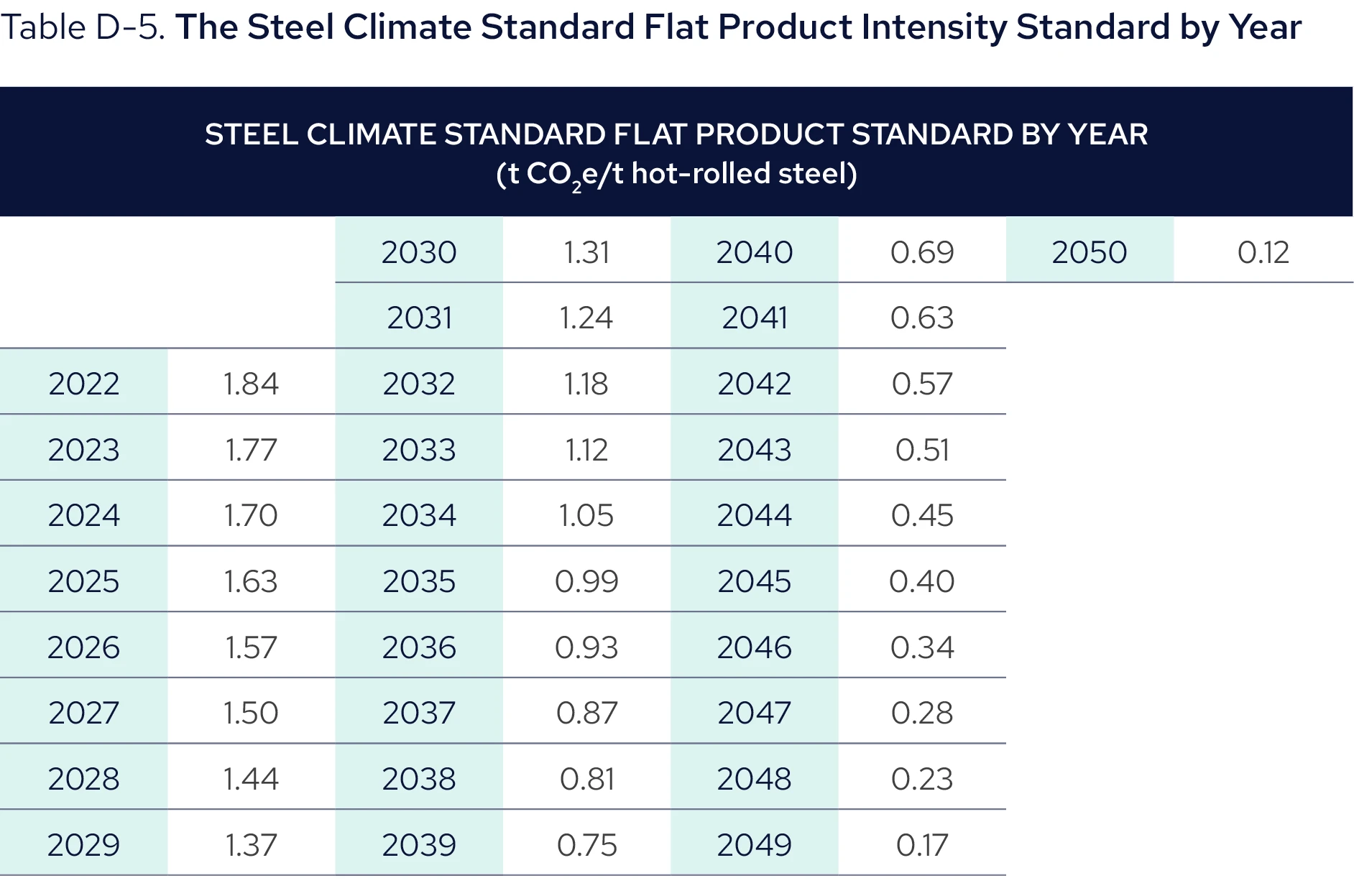

The Steel Climate Standard flat product and long product standards were developed by apportioning the Steel Climate Standard glidepath GHG intensity (t CO₂e/t hot rolled steel) value between these two product categories at the 2020 starting point and converging to the same glidepath value in 2050. The 2020 estimates of global consumption for flat and long products are provided in Table D-1.

It should be noted that the consumption data did not include high alloy specialty steel or stainless steel products. Therefore, these categories of steel products are not covered by the Steel Climate Standard at this time. Also, the product-specific values shown in Table D-1 do not align with the production values used by IEA NZE. This discrepancy is addressed by scaling the weighted average of the product mix for 2020 to the Steel Climate Standard Decarbonization Glidepath as detailed below.

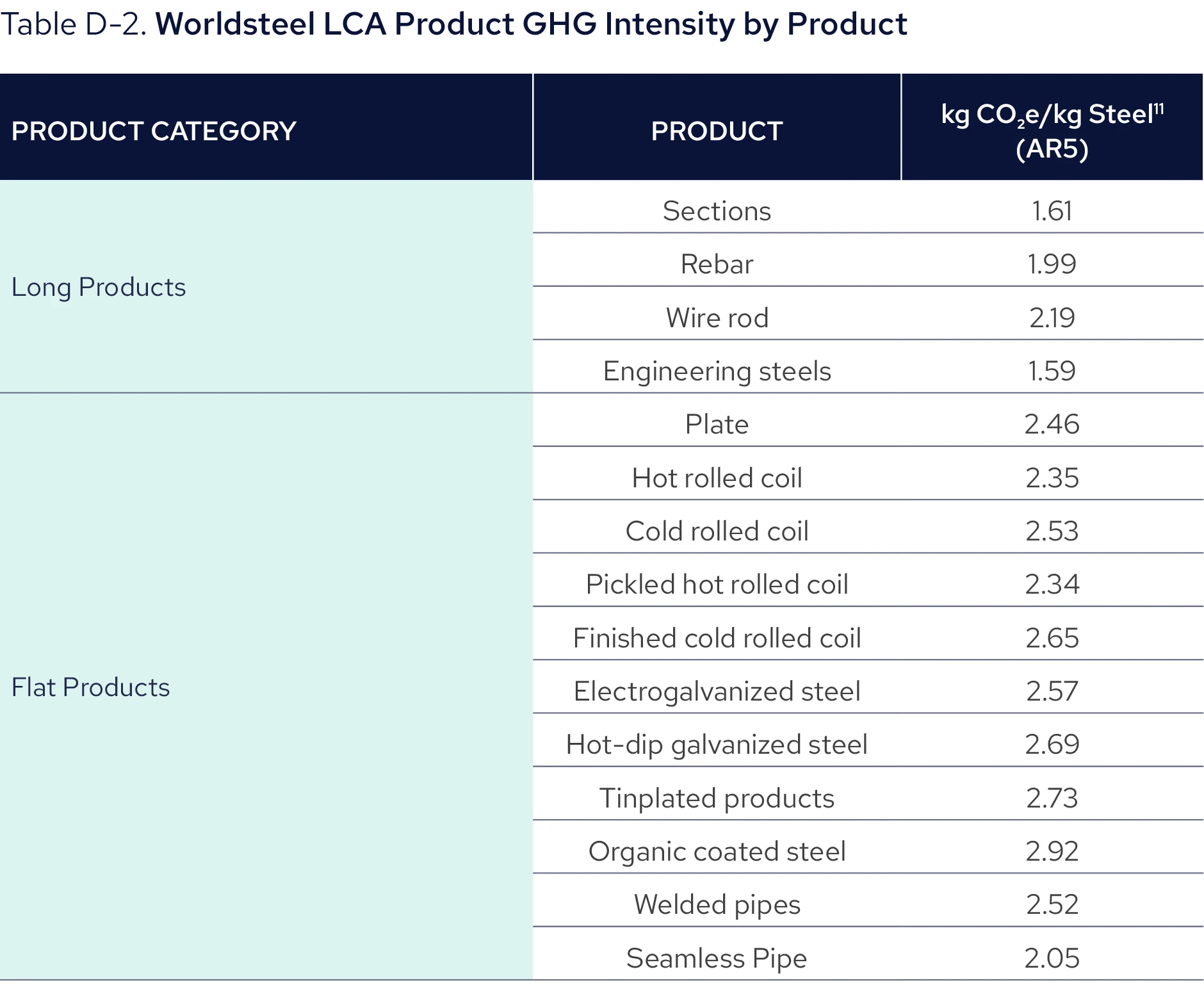

Worldsteel released its Life Cycle Inventory (LCI) Study: 2020 Data Release in May 2021.10 This study followed the data quality standards and LCA development standards outlined in ISO 14040: 2006 and 14044: 2006 with the report also receiving critical review. Individual LCAs were created for 15 product categories that cover greater than 95% of global production. A summary of the product GHG intensity (based on total emitted CO2, CH4, and N2O) from this study for each product category is shown in Table D-2.

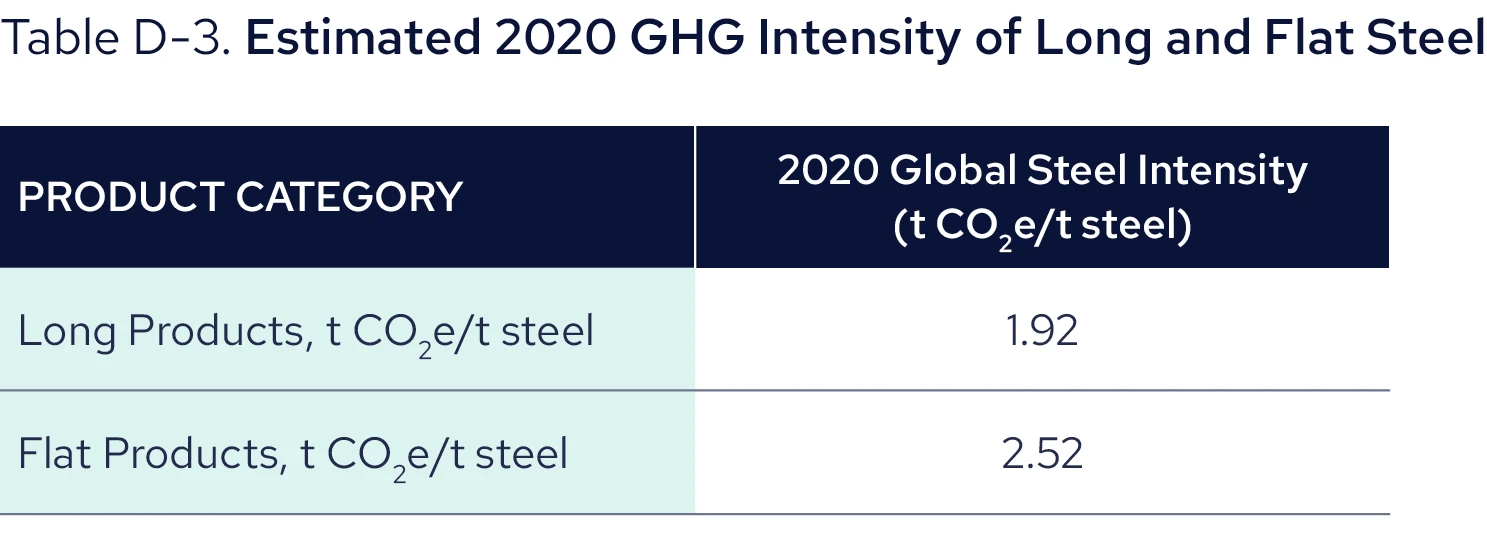

The global steel demand values shown in Table D-1 were also broken down by the product categories shown in Table D-2. Using this information, the weighted average product intensity for each product category (flat and long) was calculated as shown in Table D-3.

The estimated 2020 flat and long steel product intensities in Table D-3 were then scaled to the Steel Climate Standard Decarbonization Glidepath value for 2020 to ensure that the weighted average of flat and long product intensity values equals the Steel Climate Standard Decarbonization Glidepath intensity in 2020. A linear reduction in GHG intensity for each product category is assumed year-over-year until they converge to equal the Steel Climate Standard glidepath value in 2050. This resulted in the values provided in Tables D-4 and D-5.

Appendix E. References

1 UN Environmental Programme, 2022, “The Closing Window: Climate crisis calls for rapid transformation of societies.” Available at: https://www.unep.org/resources/emissions-gap-report-2022

2 The GHG Protocol, revised 2015, "A Corporate Accounting and Reporting Standard — Revised Edition." Available here: https://ghgprotocol.org/corporate-standard

3 IEA, 2022, “Achieving Net Zero Heavy Industry Sectors in G7 Members.” Available at: https://www.iea.org/reports/achieving-net-zero-heavy-industry-sectors-in-g7-members

4 Reheat furnace is defined in Appendix B as a “steelmaking process in which steel stock is heated to above the recrystallization temperature for hot rolling” thereby tying it specifically to hot rolling. Reheat furnaces and hot rolling are energy intensive processes that are part of manufacturing process for most steel products.

5 IEA, 2021, “Net Zero by 2050: A Roadmap for the Global Energy Sector.” Available at: https://www.iea.org/reports/net-zero-by-2050

6 SBTi, November 2022, “Steel Science-Based Target Setting Guidance.” Available at: https://sciencebasedtargets.org/resources/files/SBTi-Steel-Guidance-draft.pdf

7 Replication of the SBTi methodology for S2 intensity estimates showed an error in the intensity value derived for 2020 by SBTi and RMI. The corrected value was used for the purposes of this standard.

8 IEA, 2020, “Iron and Steel Technology Roadmap.” Available at: https://www.iea.org/reports/iron-and-steel-technology-roadmap

9 Projections of future demand for long and flat steel products developed via MetalSpans Demand modeling, January 2023, https://www.mckinsey.com/industries/metals-and-mining/how-we-help-clients/minespans/overview.

10 Worldsteel, 2021, “Life cycle inventory (LCI) study — 2020 data release.” Available here: https://worldsteel.org/wp-content/uploads/Life-cycle-inventory-LCI-study-2020-data-release.pdf

11 Intensity values are based on emissions to air totals for CO2, CH4, and N2O with AR5 global warming potentials.

12 GHG Protocol, 2011, “Corporate Value Chain (Scope 3) Accounting and Reporting Standard, Supplement to the GHG Protocol Corporate Accounting and Reporting Standard.” Available here: https://ghgprotocol.org/standards/scope-3-standard

13 GHG Protocol, 2011, “Technical Guidance for Calculating Scope 3 Emissions (Version 1.0), Supplement to the Corporate Value Chain (Scope 3) Accounting and Reporting Standard.” Available here: https://ghgprotocol.org/scope-3-technical-calculation-guidance

- Our Mission

- Overview of Standard

- Steel Climate Standard Product Certification

- Emissions Accounting for Products

- Steel Climate Standard Science-Based Emissions Target Setting

- Emissions Accounting for Targets

- Appendix A. Glossary of Terms

- Appendix B. Steel Climate Standard Boundary

- Appendix C. Steel Climate Standard Decarbonization Glidepath

- Appendix D. Basis for Steel Climate Standard Product Standards

- Appendix E. References